The development of natural fibre composites is needed to replace synthetic composites which are difficult to decompose. However, natural fibre composites have many weaknesses that need to be studied, including being brittle and easily cracked. One of the things carried out in this research is a material derived from unsaturated polyester reinforced with natural fibres from pineapple leaves and used to reduce the percentage of synthetic materials from polyester which can form composites that are easily decomposed. With this research, engineering in the engineering field such as raw materials for fishing boat bodies, tourist boat bodies, and fishing boats is very helpful. This unsaturated polyester mixture with 20% pineapple leaf fibre has the highest critical stress intensity factor of K_1c= 1,733 MPa.m0.5, an increase from K_1c= 0,779 MPa.m0.5 in pure unsaturated polyester. This material has the highest performance and can withstand good fracture strength, making it suitable for engineering applications. This research increased the toughness and crack resistance of the UP material treated with the addition of the SN mixture by 222.47%.

| Published in | American Journal of Materials Synthesis and Processing (Volume 9, Issue 2) |

| DOI | 10.11648/j.ajmsp.20240902.12 |

| Page(s) | 31-36 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Synthetic-composite, Polyester-unsaturated, Pineapple-leaf Fiber-fiber, Factor-intensity-voltage

Material No | UP Composition (% Volume) | SN Composition (% Volume) |

|---|---|---|

1 | 100 | 0 |

2 | 90 | 10 |

3 | 80 | 20 |

4 | 70 | 30 |

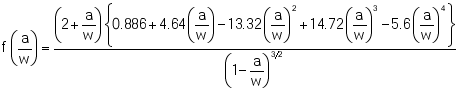

(2)

(2) UP /SN (%) | Specimens | Force (kN) | K 1c (MPa.mm0.5) | |

|---|---|---|---|---|

100/0 | 1 | 632 | 0,790 | 0,779 |

2 | 545 | 0,783 | ||

3 | 617 | 0,766 | ||

90/10 | 1 | 1363 | 1,287 | 1,207 |

2 | 1283 | 1,168 | ||

3 | 1336 | 1,167 | ||

80/20 | 1 | 1612 | 1,754 | 1,733 |

2 | 1525 | 1,763 | ||

3 | 1681 | 1,683 | ||

70/30 | 1 | 1486 | 1,435 | 1,337 |

2 | 1436 | 1,230 | ||

3 | 1530 | 1,348 | ||

Material No. | Fracture Energy (N.mm) |

|---|---|

UP/SN 100/0 | 0.182 |

UP/SN 90/10 | 0.624 |

UP/SN 80/20 | 0.837 |

UP/SN 70/30 | 0.645 |

UP | Unsaturated Polyester |

SN | Pineapple Leaf Fibre |

| [1] | Nusyirwan, H. Abral, M. Hakim, and R. Vadia, “The potential of rising husk fiber/native sago starch reinforced biocomposite to automotive component,” IOP Conf. Ser. Mater. Sci. Eng., vol. 602, no. 1, 2019, |

| [2] | N. Nusyirwan, P. Abiema, and A. Malik, “Methods Increased Fracture Toughness Thermosetting Polyester Mixture with Vi- nyl Ester for Raw Materials in Ship Bodies,” vol. 1, no. 1, pp. 43–50, 2023. |

| [3] | N. Nusyirwan, A. Peronika, H. Abral, H. Dahlan, E. Satria, and A. Sutanto, “Unsaturated Polyester Fracture Toughness Mechanism With Blending To Vinyl Ester and Mma,” ARPN J. Eng. Appl. Sci., vol. 17, no. 23, pp. 1990–1996, 2022. |

| [4] | Nusyirwan, F. Yande, H. Abral, Ihamdi, H. Dahlan, and E. Satria, “Effect of variations in load speed on fracture toughness of thermoset polyester/thermoset vinyl ester blend,” AIP Conf. Proc., vol. 2592, no. March 1996, 2023, |

| [5] | N. Nusyirwan and R. Pratama, “Study on Increasing the Cracking Resistance of Unsaturated Polyester,” vol. 7, no. 2, pp. 84–89, 2023. |

| [6] | Y. Hizhar and A. Malik, “Jurnal Polimesin strengthening materials,” vol. 21, no. 5, pp. 27–32, 2023. |

| [7] | N. Adnan, H. Abral, D. H, and E. Staria, “Identification of Mechanical Strength for Mixture of Thermoset Polyester with Thermoset Vinyl Ester due to Bending Load,” JMPM (Jurnal Mater. dan Proses Manufaktur), vol. 6, no. 1, pp. 19–25, 2022, |

| [8] | N. Nusyirwan, M. Rani, and R. Pratama, “Identification of the fracture surface of thermoset polyester due to bending load,” vol. 7, no. 1, pp. 51–58, 2022, |

| [9] | N. Nusyirwan and S. Ilham, “Study of Improving Fracture Toughness of Un-Saturated Polyester with Addition of Mixing Percentage of CPO Oils,” vol. 2, pp. 132–137, 2022. |

| [10] | H. Ardhyananta et al., “Mechanical and Thermal Properties of Unsaturated Polyester/Vinyl Ester Blends Cured at Room Temperature,” IOP Conf. Ser. Mater. Sci. Eng., vol. 202, no. 1, 2017, |

| [11] | J. Njuguna, P. Wambua, and K. Pielichowski, Cellulose Fibers: Bio- and Nano-Polymer Composites. 2011. |

| [12] | J. S. Ullett and R. P. Chartoff, “Toughening of unsaturated polyester and vinyl ester resins with liquid rubbers,” Polym. Eng. Sci., vol. 35, no. 13, pp. 1086–1097, 1995, |

| [13] | M. T. Albdiry and B. F. Yousif, “Toughening of brittle polyester with functionalized halloysite nanocomposites,” Compos. Part B Eng., vol. 160, no. October 2018, pp. 94–109, 2019, |

| [14] | Z. Zulmiardi, M. Sayuthi, F. Safriwardy, and M. Meriatna, “Uji Mekanik Komposit Serat Daun Nenas Bermatrik Resin Getah Pinus,” J. Teknol. Kim. Unimal, vol. 8, no. 1, p. 1, 2021, |

| [15] | J. Jain and S. Sinha, “Pineapple Leaf Fiber Polymer Composites as a Promising Tool for Sustainable, Eco-friendly Composite Material: Review,” J. Nat. Fibers, vol. 19, no. 15, pp. 10031–10052, 2022, |

| [16] | H. N. Dhakal and S. O. Ismail, Unsaturated polyester resins: Blends, interpenetrating polymer networks, composites, and nanocomposites. Elsevier Inc., 2019. |

| [17] | a Standard, “Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials,” Annu. B. ASTM Stand., vol. 99, no. Reapproved, pp. 1–9, 1996, |

| [18] | M. Hughes, C. A. S. Hill, and J. R. B. Hague, “The fracture toughness of bast fibre reinforced polyester composites: Part 1 Evaluation and analysis,” J. Mater. Sci., vol. 37, no. 21, pp. 4669–4676, 2002, |

APA Style

Nusyirwan, N., Hizhar, Y., Malik, A. (2025). Study of the Fracture Toughness Strength of Composites Made from Unsaturated Polyester with Pineapple Leaf Fiber Reinforcement. American Journal of Materials Synthesis and Processing, 9(2), 31-36. https://doi.org/10.11648/j.ajmsp.20240902.12

ACS Style

Nusyirwan, N.; Hizhar, Y.; Malik, A. Study of the Fracture Toughness Strength of Composites Made from Unsaturated Polyester with Pineapple Leaf Fiber Reinforcement. Am. J. Mater. Synth. Process. 2025, 9(2), 31-36. doi: 10.11648/j.ajmsp.20240902.12

AMA Style

Nusyirwan N, Hizhar Y, Malik A. Study of the Fracture Toughness Strength of Composites Made from Unsaturated Polyester with Pineapple Leaf Fiber Reinforcement. Am J Mater Synth Process. 2025;9(2):31-36. doi: 10.11648/j.ajmsp.20240902.12

@article{10.11648/j.ajmsp.20240902.12,

author = {Nusyirwan Nusyirwan and Yul Hizhar and Adam Malik},

title = {Study of the Fracture Toughness Strength of Composites Made from Unsaturated Polyester with Pineapple Leaf Fiber Reinforcement},

journal = {American Journal of Materials Synthesis and Processing},

volume = {9},

number = {2},

pages = {31-36},

doi = {10.11648/j.ajmsp.20240902.12},

url = {https://doi.org/10.11648/j.ajmsp.20240902.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ajmsp.20240902.12},

abstract = {The development of natural fibre composites is needed to replace synthetic composites which are difficult to decompose. However, natural fibre composites have many weaknesses that need to be studied, including being brittle and easily cracked. One of the things carried out in this research is a material derived from unsaturated polyester reinforced with natural fibres from pineapple leaves and used to reduce the percentage of synthetic materials from polyester which can form composites that are easily decomposed. With this research, engineering in the engineering field such as raw materials for fishing boat bodies, tourist boat bodies, and fishing boats is very helpful. This unsaturated polyester mixture with 20% pineapple leaf fibre has the highest critical stress intensity factor of K_1c= 1,733 MPa.m0.5, an increase from K_1c= 0,779 MPa.m0.5 in pure unsaturated polyester. This material has the highest performance and can withstand good fracture strength, making it suitable for engineering applications. This research increased the toughness and crack resistance of the UP material treated with the addition of the SN mixture by 222.47%.},

year = {2025}

}

TY - JOUR T1 - Study of the Fracture Toughness Strength of Composites Made from Unsaturated Polyester with Pineapple Leaf Fiber Reinforcement AU - Nusyirwan Nusyirwan AU - Yul Hizhar AU - Adam Malik Y1 - 2025/01/22 PY - 2025 N1 - https://doi.org/10.11648/j.ajmsp.20240902.12 DO - 10.11648/j.ajmsp.20240902.12 T2 - American Journal of Materials Synthesis and Processing JF - American Journal of Materials Synthesis and Processing JO - American Journal of Materials Synthesis and Processing SP - 31 EP - 36 PB - Science Publishing Group SN - 2575-1530 UR - https://doi.org/10.11648/j.ajmsp.20240902.12 AB - The development of natural fibre composites is needed to replace synthetic composites which are difficult to decompose. However, natural fibre composites have many weaknesses that need to be studied, including being brittle and easily cracked. One of the things carried out in this research is a material derived from unsaturated polyester reinforced with natural fibres from pineapple leaves and used to reduce the percentage of synthetic materials from polyester which can form composites that are easily decomposed. With this research, engineering in the engineering field such as raw materials for fishing boat bodies, tourist boat bodies, and fishing boats is very helpful. This unsaturated polyester mixture with 20% pineapple leaf fibre has the highest critical stress intensity factor of K_1c= 1,733 MPa.m0.5, an increase from K_1c= 0,779 MPa.m0.5 in pure unsaturated polyester. This material has the highest performance and can withstand good fracture strength, making it suitable for engineering applications. This research increased the toughness and crack resistance of the UP material treated with the addition of the SN mixture by 222.47%. VL - 9 IS - 2 ER -