The Eyring-Powell liquid is a type of non-Newtonian fluid. The complex flow behavior makes it useful in a variety of industrial and engineering applications such as drug manufacturing, paint and in armor construction. Blood, starch, nail polish and honey are such examples. The viscosity of these fluid changes with the rate at which the fluid shears. The need for improved heat transport fluid for industrial processes necessitates this research. The existing fluid are outdated by the advance in technology of machines. This paper modifies the classic Navier-Stokes equations to better capture the unique features of these fluids. The effect of a dual-layer structure on heat transfer in the hydromagnetic flow of an Eyring-Powell fluid near a boundary is numerically investigated. The state variable technique is used to generate and linearize the governing nonlinear differential equations as well as the applicable boundary conditions. The predictor-corrector scheme is utilized to solve the equations by calling the ode113 solver in matlab as the bvp5c function is employed for analysis. The predictor makes the first approximation which is refined by the corrector. The findings, graphically depicted, demonstrate that fluid velocity, temperature, and other parameters decrease with increasing magnetic field intensity, thermal stratification, concentration stratification, and Nusselt number.

| Published in | Fluid Mechanics (Volume 10, Issue 1) |

| DOI | 10.11648/j.fm.20251001.12 |

| Page(s) | 11-20 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Hydromagnetic, Boundary Layer, Stratification, Thermophoresis, Fluid

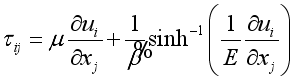

(1)

(1)  is the dynamic viscosity coefficient, and are the Eyring-Powell and rheological fluid parameters, is the shear stress tensor component and is the inverse hyperbolic sine function. From equation (1), Ali and Zaib (2019) approximated sinh-1 as

is the dynamic viscosity coefficient, and are the Eyring-Powell and rheological fluid parameters, is the shear stress tensor component and is the inverse hyperbolic sine function. From equation (1), Ali and Zaib (2019) approximated sinh-1 as  the kinematic viscosity,

the kinematic viscosity,  the thermal conductivity of the fluid,

the thermal conductivity of the fluid,  the fluid density,

the fluid density,  the acceleration due to gravity,

the acceleration due to gravity,  the volumetric expansion coefficient of the fluid, temperature, the particle volume fraction on the boundary of the magnetic field, D the Brownian motion coefficient, the ambient free stream velocity, ambient temperature, ambient concentration, μ the fluid coefficient of dynamic viscosity and the imposed magnetic field.

the volumetric expansion coefficient of the fluid, temperature, the particle volume fraction on the boundary of the magnetic field, D the Brownian motion coefficient, the ambient free stream velocity, ambient temperature, ambient concentration, μ the fluid coefficient of dynamic viscosity and the imposed magnetic field.

| Material Parameter |

| Non-Newtonian Parameter |

| Eyring-Powell Parameter |

| Dynamic Viscosity |

| Initial Magnetic Field |

| Unsteadiness Parameter |

| Dimensionless stream function |

| Dimensionless Concentration function |

| Dimesnionless Temperature function |

| Skin Friction |

| Thermal Stratification |

| Solutal Stratification |

| Density |

Ω | Local Nanomaterial Parameter |

| Similarity Variable |

| Nabla Operator |

| Velocity Vector |

Ec | Eckert Number |

Gr | Grashof Number |

Nr | Thermophoresis |

M | Magnetic field |

g | Gravitational Field Strength |

T | Temperature |

Le | Lewis Number |

F | Force |

p | Pressure |

Pr | Prandtl Number |

Nu | Nuselt Number |

Sh | Sherwood Number |

| Local Skin friction |

| Specific heat capacity |

| Reynold number |

| surface heat flux |

| surface mass flux |

k | thermal conductivity |

a,b,c | Constants |

t | time |

| Ambient Temperature, Concentration & Velocity |

(u,v) | Speed in x and y Directions |

MHD | Magnetohydrodynamic |

Matlab | Matrix Laboratory |

Eqn. | Equation |

| [1] | Ali, F and Zaib, A. Unsteady flow of an Eyring-Powell nanofluid near stagnation point past a convectively heated stretching sheet, Arab Journal of Basic and Applied Science, 2019, VOL. 26, NO. 1, 215–224, |

| [2] | Akinshilo, A. T. and Olaye, O. (2019) 'On the analysis of the Eyring Powell model-based fluid flow in a pipe with temperature-dependent viscosity and internal heat generation, Journal of King Saud University - Engineering Sciences. King Saud University, 31(3), pp. 271–279. |

| [3] | Anderson, J. D. (2005) 'Ludwig Prandtl's boundary layer, Physics Today, 58(12), pp. 42–48. |

| [4] | Asha, S. K., and Sunitha, G. (2019) 'Effect of Joule heating and MHD on peristaltic blood flow of Eyring–Powell nanofluid in a non-uniform channel', Journal of Taibah University for Science. Taylor & Francis, 13(1), pp. 155–168. |

| [5] | Babu, M. J., Sandeep, N. and Raju, C. S. K. (2016) 'Heat and mass transfer in MHD Eyring-Powell nanofluid flow due to cone in the porous medium, International Journal of Engineering Research in Africa, 19, pp. 57–74. |

| [6] | Abbas, W., & Megahed, A. M. (2021). Powell-eyring fluid flow over a stratified sheet through porous medium with thermal radiation and viscous dissipation. AIMS Mathematics, 6(12), 13464–13479. |

| [7] | Jamshed, W., Eid, M. R., Nisar, K. S., Nasir, N. A. A. M., Edacherian, A., Saleel, C. A., & Vijayakumar, V. (2021). A numerical frame work of magnetically driven Powell-Eyring nanofluid using single phase model. Scientific Reports, 11(1), 1–26. |

| [8] | Ibrahim, W. and Makinde, O. D. (2013) 'The effect of double stratification on boundary-layer flow and heat transfer of nanofluid over a vertical plate', Computers and Fluids. Elsevier Ltd, 86, pp. 433–441. |

| [9] | Javed, T. et al. (2013) 'Flow of an Eyring-Powell non-newtonian fluid over a stretching sheet, Chemical Engineering Communications, 200(3), pp. 327–336. |

| [10] | Malik, M. Y. et al. (2015) 'Mixed convection flow of MHD Eyring-Powell nanofluid over a stretching sheet: A numerical study, Dalton Transactions, 5(11). |

| [11] | Mutuku, W. N. and Makinde, O. D. (2017) 'Double stratification effects on heat and mass transfer in unsteady MHD nanofluid flow over a flat surface', Asia Pacific Journal on Computational Engineering. Springer Singapore, 4(1). |

| [12] | Ramana Reddy, J. V., Sugunamma, V. and Sandeep, N. (2018) 'Impact of short and Dufour numbers on MHD Casson fluid flow past an exponentially stretching sheet with non-uniform heat source/sink', Defect and Diffusion Forum, 388(4), pp. 14–27. |

| [13] | Waini, I., Ishak, A., & Pop, I. (2024). Eyring-Powell Fluid Flow Past a Shrinking Sheet: Effect of Magnetohydrodynamic (MHD) and Joule Heating. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 116(1), 64–77. |

| [14] | Siddiqui, A. M., Haroon, T., & Zeb, M. (2014). Analysis of eyring-powell fluid in helical screw rheometer. The Scientific World Journal, 2014. |

| [15] | Hameed, M. and Nadeem, S. (2007) 'Unsteady MHD flow of non-Newtonian fluid on a porous plate', Journal of Mathematical Analysis and Applications, 325(1), pp. 724–733. |

| [16] | Mahanthesh, B., Gireesha, B. J. and Gorla, R. S. R. (2017) 'Unsteady three-dimensional MHD flow of a nano Eyring-Powell fluid past a convectively heated stretching sheet in the presence of thermal radiation, viscous dissipation, and Joule heating, Journal of the Association of Arab Universities for Basic and Applied Sciences. University of Bahrain, 23, pp. 75–84. |

| [17] | Ramzan, M., Bilal, M., & Chung, J. D. (2017). Radiative flow of powell-eyring magneto-nanofluid over a stretching cylinder with chemical reaction and double stratification near a stagnation point. PLoS ONE, 12(1), 1–19. |

| [18] | Srinivasacharya, D. and Surender, O. (2015) 'Effect of double stratification on mixed convection boundary layer flow of a nanofluid past a vertical plate in a porous medium', Applied Nanoscience (Switzerland), 5(1), pp. 29–38. |

| [19] | Verma, A. K., Gautam, A. K., Bhattacharyya, K., Banerjee, A., & Chamkha, A. J. (2021). Boundary layer flow of non-Newtonian Eyring–Powell nanofluid over a moving flat plate in Darcy porous medium with a parallel free-stream: Multiple solutions and stability analysis. Pramana - Journal of Physics, 95(4). |

| [20] | Jaber, K. K. (2014). Effects of Viscous Dissipation and Joule Heating on Mhd Flow of a Fluid With Variable Properties Past A stretching Vertical Plate. 10(33), 383–393. |

| [21] | Aznidar Ismail, N. S., Abd Aziz, A. S., Ilias, M. R., & Soid, S. K. (2021). MHD boundary layer flow in double stratification medium. Journal of Physics: Conference Series, 1770(1). |

APA Style

Wekesa, S. W., Mutuku, W. N. (2025). Hydromagnetic Boundary Layer Flow and Heat Migration of Dual Stratified Eyring-Powell Fluid. Fluid Mechanics, 10(1), 11-20. https://doi.org/10.11648/j.fm.20251001.12

ACS Style

Wekesa, S. W.; Mutuku, W. N. Hydromagnetic Boundary Layer Flow and Heat Migration of Dual Stratified Eyring-Powell Fluid. Fluid Mech. 2025, 10(1), 11-20. doi: 10.11648/j.fm.20251001.12

@article{10.11648/j.fm.20251001.12,

author = {Simon Waswa Wekesa and Winfred Nduku Mutuku},

title = {Hydromagnetic Boundary Layer Flow and Heat Migration of Dual Stratified Eyring-Powell Fluid

},

journal = {Fluid Mechanics},

volume = {10},

number = {1},

pages = {11-20},

doi = {10.11648/j.fm.20251001.12},

url = {https://doi.org/10.11648/j.fm.20251001.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.fm.20251001.12},

abstract = {The Eyring-Powell liquid is a type of non-Newtonian fluid. The complex flow behavior makes it useful in a variety of industrial and engineering applications such as drug manufacturing, paint and in armor construction. Blood, starch, nail polish and honey are such examples. The viscosity of these fluid changes with the rate at which the fluid shears. The need for improved heat transport fluid for industrial processes necessitates this research. The existing fluid are outdated by the advance in technology of machines. This paper modifies the classic Navier-Stokes equations to better capture the unique features of these fluids. The effect of a dual-layer structure on heat transfer in the hydromagnetic flow of an Eyring-Powell fluid near a boundary is numerically investigated. The state variable technique is used to generate and linearize the governing nonlinear differential equations as well as the applicable boundary conditions. The predictor-corrector scheme is utilized to solve the equations by calling the ode113 solver in matlab as the bvp5c function is employed for analysis. The predictor makes the first approximation which is refined by the corrector. The findings, graphically depicted, demonstrate that fluid velocity, temperature, and other parameters decrease with increasing magnetic field intensity, thermal stratification, concentration stratification, and Nusselt number.

},

year = {2025}

}

TY - JOUR T1 - Hydromagnetic Boundary Layer Flow and Heat Migration of Dual Stratified Eyring-Powell Fluid AU - Simon Waswa Wekesa AU - Winfred Nduku Mutuku Y1 - 2025/06/23 PY - 2025 N1 - https://doi.org/10.11648/j.fm.20251001.12 DO - 10.11648/j.fm.20251001.12 T2 - Fluid Mechanics JF - Fluid Mechanics JO - Fluid Mechanics SP - 11 EP - 20 PB - Science Publishing Group SN - 2575-1816 UR - https://doi.org/10.11648/j.fm.20251001.12 AB - The Eyring-Powell liquid is a type of non-Newtonian fluid. The complex flow behavior makes it useful in a variety of industrial and engineering applications such as drug manufacturing, paint and in armor construction. Blood, starch, nail polish and honey are such examples. The viscosity of these fluid changes with the rate at which the fluid shears. The need for improved heat transport fluid for industrial processes necessitates this research. The existing fluid are outdated by the advance in technology of machines. This paper modifies the classic Navier-Stokes equations to better capture the unique features of these fluids. The effect of a dual-layer structure on heat transfer in the hydromagnetic flow of an Eyring-Powell fluid near a boundary is numerically investigated. The state variable technique is used to generate and linearize the governing nonlinear differential equations as well as the applicable boundary conditions. The predictor-corrector scheme is utilized to solve the equations by calling the ode113 solver in matlab as the bvp5c function is employed for analysis. The predictor makes the first approximation which is refined by the corrector. The findings, graphically depicted, demonstrate that fluid velocity, temperature, and other parameters decrease with increasing magnetic field intensity, thermal stratification, concentration stratification, and Nusselt number. VL - 10 IS - 1 ER -