Abstract

Micro-hydropower plants are a highly favorable alternatives to solving the electrification problems in rural areas where we have the potential and also to satisfy the electricity demand of the populations in several developing countries such as Cameroon. Given the challenges related to the accessibility and selection of micro-hydraulic turbine technologies, the potential of micro hydropower available in Cameroon remains almost untapped. Our study proposes a methodology using fuzzy MCDM methods for the selection of a micro-hydraulic turbine technology for a micro-hydropower project study in Cameroon. The development of a transparent and objective decision-making process, taking into consideration the technical, economic, environmental criteria, as well as uncertainties and subjective preferences of stakeholders using fuzzy MCDM methods, namely fuzzy AHP, TOPSIS fuzzy and fuzzy VIKOR, allowed us to evaluate several hydraulic micro-turbine technologies. It emerges from this study that PAT technology is the best option for the project, with a proximity coefficient of 0.554652 and a VIKOR index of 0.422592 obtained respectively by the F-TOPSIS and F-VIKOR methods, followed by the Pelton turbine with a proximity coefficient of 0.391916 and a VIKOR index of 0.558388. The results showed that the fuzzy MCDM approach offers a powerful decision support tool in the context of micro-hydropower projects, making it possible to identify the most appropriate technologies and to maximize socio-economic and environmental benefits. This approach could also be applicable in other developing countries with the potential of pico and micro hydroelectricity to improve rural electrification.

Keywords

Micro Hydropower, Micro Hydraulic Turbine, Fuzzy MCDM Methods, Rural Electrification

1. Introduction

Access to energy plays a vital role in the economic and social progress of a country or locality. Despite its significant potential in renewable energy, Sub-Saharan Africa (SSA) faces major challenges in electrification. According to the International Energy Agency (IEA), nearly three-quarters of the population in thirteen SSA countries still lack access to electricity

| [1] | A. Korkovelos, D. Mentis, S. Siyal and R. H, "A geospatial assessment of small-scale hydropower potential in sub-saharan," Energies, no. 111, pp. 1-21, 2018. https://doi.org/10.3390/en11113100 |

[1]

. Cameroon, like many other Sub-Saharan African countries, struggles to meet the growing energy demands of its population. In recent years, the situation has worsened due to the consequences of the COVID-19 pandemic and the war in Ukraine, which have impacted finances and slowed progress in providing access to electricity

| [2] | Hugo LE PICARD, "Nouveau paradigme de l ’électrification en Afrique subsaharienne Comment les systèmes hybrides décentralisés changent-ils la donne ?’," l’Institut français des relations internationales (Ifri) et le Policy Center for the New South, FRANCE, 2022. |

[2]

.

However, hydropower presents a promising solution to address this lack of access to energy, especially in countries like Cameroon where hydraulic resources are abundant. Hydropower offers numerous advantages, including reduced greenhouse gas (GHG) emissions, high efficiency, low operating and maintenance costs, and high reliability

. The global installed capacity from hydropower sources is estimated at 1,292 GW in 2018, representing 62% of global electricity production from renewable energy sources (RES).

| [4] | I. H. Association, "Hydropower Status Report," IHA, London, UK, 2019. |

[4]

In Africa, pico and micro hydropower plants could play a crucial role in meeting electricity needs, particularly in regions where hydrological conditions are favorable.

| [5] | H. L. Tidjani, M. M. Raïssa, K. Joseph, O. Hamandjoda and A. E. Patrice, "Selection of a Suitable Material by a Multi-Criteria Decision Aid Method (Mcdm) for the Manufacture of the Buckets of a Micro Pelton Turbine," American Journal of Energy and Natural Resources (AJENR), 2023. https://doi.org/10.54536/ajenr.v2i1.1101 |

[5]

. Despite this potential, decentralized rural electrification of remote areas remains a major challenge. Countries with perennial rivers in mountainous topography could benefit from pico- and micro-hydropower for rural electrification, using mini-grid systems. Turbine types suitable for these systems include mass-produced propeller systems

| [6] | W. Rijsenbeek, "Pico hydro systems in Vietnam," rural energy supply models, 2001. |

[6]

, turbine-type pumps (PAT)

| [7] | Williams A, "Pumps as turbines," a user’s guide. 2nd ed. London:ITDG, london, 2003. |

[7]

and

| [8] | A. Asad, Y. Jianping and H. Javed, "Small hydropower generation using pump as turbine; a smart solution for the development of Pakistan’s energy," Heliyon, vol. 9, pp. 1-16, 2023. https://doi.org/10.1016/j.egypro.2017.11.042 |

[8]

, locally manufactured Pelton wheels, and home-made systems based on impulse turbines

| [9] | A. A. Williams and R. Simpson, "Pico hydro - reducing technical risks for rural electrification," Renewable Energy, vol. 32, pp. 1986-1991, 2009. https://doi.org/10.1016/j.renene.2008.12.011 |

| [10] | C. Achebe, O. Okafor and E. Obika, "Design and implementation of a crossflow turbine for Pico hydropower electricity generation," Heliyon, vol. 6, pp. 1-13, 2020. https://doi.org/10.1016/j.heliyon.2020.e04523 |

[9, 10]

.

Despite their valuable role in reducing global greenhouse gas emissions, the widespread adoption of small hydropower plants in developing countries is constrained by limited access to technology and the particularly complex task of selecting the most suitable turbine – a decision frequently described as "one of the most difficult in hydropower plant design"

| [11] | Y. Yildiz V, "Numerical Simulation Model of Run of River Hydropower Plants: Concepts, Numerical Modeling, Turbine System and Selection, and Design Optimization," University of California, Oakland, CA, USA, 2015. https://escholarship.org/uc/item/0jb5v4df |

[11]

. This task is even more complex given the often contradictory and interdependent economic, technical and environmental criteria.

Several researchers have studied the selection of hydraulic turbines taking into account various criteria.

| [12] | S. Sangal, G. A. and D. Kumar, "Review of Optimal Selection of Turbines for Hydroelectric Projects.," Int. J. Emerg. Technol. Adv. Eng., vol. 3, pp. 424–430, 2013. |

[12]

, explored the optimal selection of hydraulic turbines.

| [13] | A. Adejumobi and D. Shobayo, "Optimal Selection of Hydraulic Turbines for Small Hydro Electric Power Generation—A Case Study of Opeki River, South Western Nigeria.," Niger. J. Technol., vol. 34, pp. 530-542, 2015. http://dx.doi.org/10.4314/njt.v34i3.15.15 |

[13]

, studied the optimal choice of hydraulic turbines for small hydropower projects, based on a case study in Nigeria.

, considered the criteria of investment cost per kW of production, ease of installation, local manufacturing and local repair/maintenance capacity to approach the turbine selection process.

Traditionally, the selection of hydroelectric turbines has relied on prior knowledge and simplified calculation methods. However, the increasing complexity of hydroelectric projects and the multiplication of stakeholders require a more rigorous and flexible approach. MCDM (Multi-Criteria Decision Support) methods offer a powerful tool to make informed and robust decisions by taking into account multiple, often conflicting criteria and objectives.

| [15] | M. Yenugula, S. Sahoo and S. Goswami, "Cloud computing in supply chain management: Exploring the relationship.," Management Science Letters, vol. 13, no. 3, pp. 193-210, 2023. http://dx.doi.org/10.5267/j.msl.2023.4.003 |

[15]

. Previous studies have demonstrated the effectiveness of MCDM methods in the selection of hydraulic turbines.

| [16] | G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022. https://dx.doi.org/10.3390/en15197383 |

| [17] | S. Williamson, B. Stark and J. Booker, "Low Head Pico Hydro Turbine Selection Using a Multi-Criteria Analysis.," Renew. Energy, vol. 61, pp. 43–50, 2014. https://doi.org/10.1016/j.renene.2012.06.020 |

[16, 17]

.

Traditional MCDM methods

| [18] | C. Kahraman, G. Büyükzokan and N. Y. et Ates, "A two phase multi-attribute decision making approach for new product introduction.," Information Sciences,, vol. 177, pp. 1567–1582, 2007. https://doi.org/10.1016/j.ins.2006.09.008 |

| [19] | T. Boumedyen, "La méthode PROMETHEE comme outil d'aide à la décision multicritère," Revue Algérienne d’Economie et de Management, vol. 8, pp. 1-11, 2017. |

[18, 19]

can be limited by the uncertainty and subjectivity inherent in the data used for technology selection. For instance, experts may hold differing opinions on the relative importance of selection criteria, and site conditions can be imprecise. These limitations make it challenging to apply traditional MCDM methods in contexts where decision-making requires managing imprecision and fuzziness. Fuzzy MCDM methods, such as fuzzy AHP

| [20] | S. S. Goswami and D. K. Behera, "Evaluation of the best smartphone model in the market by integrating fuzzy AHP and PROMETHEE decision-making approach. Decision," Decision, vol. 48, pp. 71-96, 2021. https://doi.org/10.1007/s40622-020-00260-8 |

[20]

, fuzzy TOPSIS

| [21] | A. M. Pakdin, "Project selection for oil-fields development by using the AHP and fuzzy TOPSIS methods," Expert Systems with Applications, vol. 37, pp. 6218–6224, 2010. https://doi.org/10.1016/j.eswa.2010.02.103 |

| [22] | Y. Solangi, Q. Tan, N. Mirjat and S. Ali, "Evaluating the Strategies for Sustainable Energy Planning in Pakistan: An Integrated SWOT-AHP and Fuzzy-TOPSIS Approach.," Journal of Cleaner Production, vol. 236, pp. 1-14, 2019. |

[21, 22]

and fuzzy VIKOR

, offer a more flexible and robust approach to handling uncertainty and subjectivity in expert judgments. Nevertheless, the application of these fuzzy MCDM methods remains limited in the field of micro-hydro turbine technology selection.

This study aims to bridge this gap by proposing a novel hybrid fuzzy MCDM methodology, combining the F-AHP, F-TOPSIS, and F-VIKOR methods, for selecting micro-hydro turbine technology tailored to the specific conditions of a given site. This combination of different fuzzy MCDM methods for selecting micro-hydro turbines provides a more comprehensive and robust decision-making framework for stakeholders involved in the project. This innovative methodology is applicable not only to Cameroon but also to other countries with pico or micro-hydroelectric sites, this latter can also be applicable in various fields for selection.

The methodology was applied using Excel 2020, considering the specific conditions of the mountainous terrain in western Cameroon. We selected impulse turbines and PATs, which are often most suitable due to their local accessibility, as alternatives: A1: Pelton turbine, A2: Banki or Crossflow turbine, A3: Turgo turbine, A4: PAT turbine, A5: Archimedes screw. Our study seeks to optimize turbine technology selection for the case study by evaluating various alternatives based on predefined criteria.

2. Literature Review

2.1. Description of Hydraulic Turbines

Water turbines extract energy from moving water by converting hydraulic pressure into mechanical energy. Two main families of turbines are used for electricity generation: Reaction turbines: This type of turbine, which includes Francis, Bulb, Kaplan models, is submerged in water and uses the water pressure to create a rotational force. Impulse turbines: These turbines, such as Pelton, Turgo, Crossflow and Pumps-as-Turbines (PAT) models, are installed above the water and operate by capturing the kinetic energy of a high-speed water jet

| [24] | M. A. S, M. B. C. Cherchia and M. Swindleb, "Recent innovations and trends in in-conduit hydropower technologies and their applications in water distribution systems," Journal of Environmental Management, vol. 228, pp. 416–428, 2018. https://doi.org/10.1016/j.jenvman.2018.08.078 |

[24]

. The rapid development of impulse turbines in recent years is related to their adaptability to micro-hydropower projects, their low manufacturing cost and their simplified maintenance.

| [25] | A. Elbatran, O. Yaakob, A. Y. M. and H. Shabara, "Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review," Renewable and Sustainable Energy Reviews, vol. 43, pp. 40-50, 2015. http://dx.doi.org/10.1016/j.rser.2014.11.045 |

[25]

. For this reason, our study focused on hydraulic impulse turbines and PATs.

2.2. Description of Impulse Turbines

Unlike reaction turbines, impulse turbines are not submerged in water. They are usually installed above water, as they are not designed to operate with downstream pressure.

| [26] | A. W. Dametew, "Design and Analysis of Small Hydro Power for Rural electrification," Global Journal of Researches in Engineering F Electrical and Electronics Engineering, vol. 16 Issue, pp. 1-23, 2016. |

[26]

The operation of impulse turbines is based on the transformation of the head height into a high-speed water jet, which hits the turbine blades at a specific point during their rotation.

2.3. Technologies of Hydraulic Impulse Turbines and PAT Applicable to Micro Hydroelectric Power Plants

Hydraulic impulse turbines and PATs (Pumps-as-Turbines) offer interesting solutions for micro hydropower plants, thanks to their adaptability, low cost and ease of maintenance. Here are some examples of promising technologies

| [25] | A. Elbatran, O. Yaakob, A. Y. M. and H. Shabara, "Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review," Renewable and Sustainable Energy Reviews, vol. 43, pp. 40-50, 2015. http://dx.doi.org/10.1016/j.rser.2014.11.045 |

[25]

. Pelton turbines with high efficiency for large water falls (over 100 meters). Robust and simple construction, which allows local manufacturing. They may require precise adjustments for optimal optimization. Turgo turbines, more suitable for large water flows than a Pelton turbine. Better performance for medium water falls (between 30 and 100 meters). They are generally more complex and expensive to build than a Pelton turbine. Crossflow turbines, they allow energy to be produced from relatively small water falls (between 10 and 50 meters). Ideal for large water flows. They are generally less efficient than Pelton or Turgo turbines. Pumps-as-Turbines (PAT), they are flexible and versatile solutions for micro hydroelectric power plants. Allows the use of existing equipment (pump) for electricity production. The efficiency of PATs in turbine mode is often lower than that of conventional impulse turbines.

| [24] | M. A. S, M. B. C. Cherchia and M. Swindleb, "Recent innovations and trends in in-conduit hydropower technologies and their applications in water distribution systems," Journal of Environmental Management, vol. 228, pp. 416–428, 2018. https://doi.org/10.1016/j.jenvman.2018.08.078 |

[24]

.

We present some hydraulic impulse turbine technologies and PATs applicable in micro hydroelectric power plants.

Figure 1. a) Cross flow turbine, b) Pelton turbine, c) Turgo turbine, d) Archimedes screw.

2.4. Review of Hydraulic Turbine Technology Selection Methodologies

The selection of appropriate hydro turbine technologies for micro hydropower can be affected by several factors, including site location and operating regimes

| [27] | R. Uhunmwangho, M. Odje and K. Okedu, "Comparative Analysis of Mini Hydro Turbines for Bumaji Stream, Boki, Cross River State, Nigeria.," Sustain. Energy Technol. Assess, vol. 27, pp. 102-108, 2018. |

[27]

. We distinguish several traditional methods of selecting a hydro turbine for a site.

2.4.1. Methods Based on Technical Criteria

This method uses tables and graphs to compare the performance of different turbines based on technical criteria such as head, water flow, efficiency, rotational speed, specific speed value (ns), which is defined as the speed in rpm at which a turbine of similar design would operate, etc.

| [27] | R. Uhunmwangho, M. Odje and K. Okedu, "Comparative Analysis of Mini Hydro Turbines for Bumaji Stream, Boki, Cross River State, Nigeria.," Sustain. Energy Technol. Assess, vol. 27, pp. 102-108, 2018. |

| [12] | S. Sangal, G. A. and D. Kumar, "Review of Optimal Selection of Turbines for Hydroelectric Projects.," Int. J. Emerg. Technol. Adv. Eng., vol. 3, pp. 424–430, 2013. |

[27, 12]

it also uses turbine-specific performance curves to determine which one offers the best efficiency for the site conditions.

Figure 3. Hydraulic turbine selection table based on specific speed.

Figure 4. Nomogram for selection of hydraulic turbines.

2.4.2. Methods Based on Economic Criteria

This method which includes life cycle cost analysis (LCC) and profitability analysis uses all costs associated with the turbine, including investment, operating and maintenance costs, over the life of the project. And financial indicators such as internal rate of return (IRR) and net present value (NPV) to assess the economic viability of the project.

2.4.3. Methods Based on Environmental Criteria

This method includes life cycle assessment (LCA) which considers the environmental impact of the turbine throughout its life cycle including manufacturing, operation, maintenance and recycling. Considering the progress of research work regarding the selection of hydraulic turbine involving multiple factors, other selection methods have been proposed in the literature, such as MCDM methods.

and

| [16] | G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022. https://dx.doi.org/10.3390/en15197383 |

[16]

.

2.4.4. Multi-criteria Methods

Hierarchical Analysis Methods (HAM); this method structures the selection problem into a hierarchy of criteria and alternatives, then uses expert judgments to prioritize the criteria and alternatives

| [16] | G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022. https://dx.doi.org/10.3390/en15197383 |

[16]

. Ranking methods: This method ranks turbines based on their performance on each criterion, then uses a ranking method (e.g., Borda ranking) to determine the best turbine.

.

2.4.5. Literature Review on MCDM in Hydropower

In the literature, it is noted that multi-criteria decision making (MCDM) is already widely used to solve complex decision-making problems in the field of renewable energy involving quantitative and qualitative factors. We have

| [28] | E. Ozer, P. E. AKTAS, K. Mehmet and C. GENCER, "A Literature Review: Wind Energy Within the Scope of MCDM Methods," Journal of Science, vol. 36, no. 4, pp. 1578-1599, 2023. https://doi.org/10.35378/gujs.1090337 |

[28]

which offers a complete synthesis study of the work on wind energy and MCDM methods,

| [29] | D. Sinem, B. Ferhat and S. S. C., "MCDM analysis of wind energy in Turkey: decision making based on environmental impact," Environmental Science and Pollution Research vol. 25, pp. 19753–19766, 2018. https://doi.org/10.1007/s11356-018-2004-4 |

[29]

uses a combination of (GIS) and (MCDM) methodologies, for decision-making based on the environmental impact of wind energy in Türkiye.

| [30] | A. Rubio-Aliaga, M. S. García-Cascales and J. M. Sanchez-Lozano, "MCDM-based multidimensional approach for selection of optimal groundwater pumping systems: Design and case example," Renewable Energy, vol. 163, pp. 213-224, 2021. https://doi.org/10.1016/j.renene.2020.08.079 |

[30]

proposes a multi-criteria decision-making method (MCDM) based (AHP) and (TOPSIS) for the selection of optimal groundwater pumping systems in southeastern Spain. Regarding hydropower, several works have been carried out on the selection of the best locations or sites for hydropower projects, such as

| [31] | C. D. Iweh, G. C. S. Ahouansou and R. Houèchénè, "Optimum Site Selection of Hybrid Solar Photovoltaic (PV) - Hydro Power Plants in off Grid Locations in Cameroon using the Multi-Criteria Decision Analysis (MCDA," Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, vol. 45, no. 3, 2023. https://doi.org/10.1080/15567036.2023.2224739 |

[31]

who used the hybrid AHP-TOPSIS method to select optimum site selection of hybrid solar photovoltaic (PV).

| [32] | U. Nzotcha, J. Kenfack and M. B. Manjia, "Integrated multi-criteria decision-making methodology for pumped hydro energy storage plant site selection from a sustainable development perspective with an application," Renewable and Sustainable Energy Reviews, vol. 112, p. 930–947, 2019. https://doi.org/10.1016/j.rser.2019.06.035 |

[32]

uses the AHP and ELECTRE III multi-criteria decision support technique to determine the choice of the best site for the development of pumped storage hydro-energy (PHES).

| [33] | B. Wang, I. Nistor, T. Murty and Y.-M. Wei, "Efficiency assessment of hydroelectric power plants in Canada: a multi criteria decision making approach," approach. Energy Econ., vol. 46, pp. 112-121, 2014. https://doi.org/10.1016/j.eneco.2014.09.001 |

[33]

uses TOPSIS to analyze the overall efficiency of hydroelectric production and compare five provinces in Canada,

| [34] | R. P. N. H. P. Singh, "Decision aid for hydropower project prioritization in Nepal by applying Visual PROMETHEE," Int. J. Multicriteria Decis. Mak. 6, 316–342, vol. 6, pp. 316–342, 2016. https://dx.doi.org/10.1504/IJMCDM.2016.081389 |

[34]

used PROMETHEE to evaluate and rank six small hydropower projects in Nepal.

uses ELECTRE to select the most sustainable small hydropower system in the Prokletije region (Montenegro).

| [36] | Y. Wang, S. Tao, X. Chen, F. Huang, X. Xu and al, "Method multi-criteria decision-making method for site selection analysis and evaluation of urban integrated energy stations based on geographic information system," Renewable Energy, vol. 194, pp. 273-292, 2022. https://doi.org/10.1016/j.renene.2022.05.087 |

[36]

uses AHP and improved TOPSIS multi-criteria decision-making method for the selection of a site for integrated urban energy plants based on a geographic information system.

, proposed the VIKOR method to facilitate decision-making for decision-makers in a hydroelectric plant design process. Regarding the selection of hydraulic turbines

use MCDM methods to select the best hydraulic turbine technology based on quantitative criteria.

| [16] | G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022. https://dx.doi.org/10.3390/en15197383 |

[16]

Combined MCDM AHP and fuzzy VIKOR methods to propose a cropping method for hydraulic turbine selection. We also

| [38] | P. Adhikary, S. Kundu, P. K. Roy and A. Mazumdar, "Optimum selection of hydraulic turbine manufacturer for SHP: MCDA or MCDM tools," World Applied Sciences Journal, vol. 28, no. 7, pp. 914-919, 2014. https://doi.org/10.5829/idosi.wasj.2013.28.07.1373 |

[38]

who proposed an MCDA or MCDM tools analysis model for the selection of hydroelectric turbine manufacturers for small-scale hydropower production. In this same launch

| [39] | P. Adhikary, P. K. Roy and A. Mazumdar, "Turbine Supplier Selection For Small Hydro Project:" International Journal of Applied Engineering Research, vol. 10, no. 5, pp. 13109-13122, 2015. |

[39]

proposed a MCDM method consisting of ELECTRE, PROMETHEE for the choice of the supplier of hydraulic turbines for small hydroelectricity projects. To prioritize maintenance work on hydroelectric power plants

| [40] | R. F. d. Silva, M. M. Bellinello and G. F. M. d. Souza, "Deciding a Multicriteria Decision-Making (MCDM) Method to Prioritize Maintenance Work Orders of Hydroelectric Power Plants," energies, vol. 14, pp. 2-22 2021. https://doi.org/10.3390/en14248281 |

[40]

, use multi-criteria decision-making (MCDM) methods.

Although the literature reveals the use of MCDM to solve different types of decision-making problems regarding the selection of hydroelectric and hydro turbine technologies, these works remain limited. Thus, this paper aims at defining an MCDM model consisting of FAHP combined with Fussy TOPSIS and Fussy VIKOR that can exhaustively select the best alternative among impulse turbines and PATs for application in our case study. Hence our interest in this research.

3. Conceptual Framework

This section presents the fuzzy MCDM methods that we will use to propose a methodology that we can use for the selection of the appropriate hydraulic turbine or PAT for our case study. Since the fuzzy linguistic scales reflect the subjective nature of the criteria, a fuzzy triangular importance scale (see table below) was implemented to develop the hierarchical structure and comparison matrix for the MCDM problem.

Table 1. The fuzzy triangular linguistic importance scale.

Linguistic scale | TFN Scale | Reciprocal scale of TFNs |

Very weak | (1,1,1) | (1,1,1) |

Weak | (1,1,3) | (1/3,1,1) |

Moderately poor | (1,3,5) | (5/2.1/3.1) |

AVERAGE | (3,5,7) | (1/7,1/5,1/3) |

Moderately high | (5,7,9) | (1/9,1/7,1/5) |

High | (7,9,9) | (1/9,1/9,1/7) |

3.1. FAHP Method

The FAHP method widely applied in many complex decision-making problems to compare criteria with each other and establish priorities is used in our study to determine the weights of the evaluation criteria of hydraulic turbines and PAT, as done by

| [41] | Y. H. Chang, C. Cheng and T. Wang, "Performance evaluation of international airports in the region of East Asia.," Proceedings of Eastern Asia Society for Transportation Studies, vol. 4, pp. 213–230, 2003. |

[41]

and

| [42] | T. Y. Chou and G. S. Liang, "Application of a fuzzy multi-criteria decision-making model for shipping company performance evaluation.," Maritime Policy & Management, 28, 375–392., vol. 4, p. 375–392., 2001. |

[42]

. The different stages of the FAHP are presented below.

Step 1. Construct the hierarchy structure for our MCDM problem and the pairwise comparison matrix of each criterion using Triangular Fuzzy Importance Scale,

Table 1.

Step 2. The attributes' fuzzy geometric mean matrix is calculated using Equation

3. After geometric mean is used to calculate the weight equation

4.

(1)

(2)

Step 3. De-fuzzy number for FTNs is calculated using center of area method by using equation

3 and normalized using 4.

3.2. TOPSIS Fuzzy Method

The fuzzy method TOPSIS (Order Preference Technique by Similarity with the Ideal Solution) and its extensions are developed in our study to solve classification and justification problems as shown in his works whose references follow

| [43] | G. Büyükzokan, O. Feyzioglu and E. Nebol, "Selection of the strategic alliance partner in logistics value chain," ternational Journal of Production Economics, vol. 113, p. 148–158, 2008. |

| [18] | C. Kahraman, G. Büyükzokan and N. Y. et Ates, "A two phase multi-attribute decision making approach for new product introduction.," Information Sciences,, vol. 177, pp. 1567–1582, 2007. https://doi.org/10.1016/j.ins.2006.09.008 |

[43, 18]

. The reason for using a triangular fuzzy number is simply its modeling which turns out to be an effective way to formulate decision problems when the available information is subjective and imprecise.

| [44] | H. Y. and C. H. Y. e. W. S., "A survey and optimization-based evaluation of development strategies for the air cargo industry.," International journal of Production Economics, 106, 550–562, vol. 106, p. 550–562, 2007. https://doi.org/10.1016/j.ijpe.2006.06.016 |

[44]

. The different steps of the TOPSIS fuzzy method are presented below.

Step1. Take being two fuzzy numbers, so their mathematical relationship is as follows:

(5)

(6)

(7)

Step 2. Take to be a TFNs with i ϵ I. Then normalize the fuzzy number of each, as shown below.

Where i = 1.2, 3, …, m and j = 1.2, 3, …, n.

For favorable criteria the normalization process is presented as:

(10)

(Favorable type criteria)

For unfavorable criteria the normalization process is presented as follows:

(11)

(Unfavorable type criteria).

Step 3. Obtaining the weighted normalized fuzzy decision matrix for each sub-factor:

Where i = 1.2, 3, …, m and j = 1.2, 3, …, n.

Here 14 is

Step 4. Identify the distance between the fuzzy positive ideal solution () and fuzzy negative ideal solution (.

Here, the distance between two TFNs is defined as follows:

d(16)

Step 5. Calculation of the proximity coefficient (CCi) for each alternative using the following formula:

Where i=1, 2, 3, …, m, is the distance from the ideal positive fuzzy solution and is the distance from an ideal negative fuzzy solution.

Step 6. Prioritize the hydraulic turbines in descending order of valuation and select the best hydraulic turbine..

3.3. VIKOR Fuzzy Method

The VIKOR (Multi-Criteria Optimization and Tradeoff Ranking) method is based on MCDM tradeoff programming, as demonstrated in

and

| [46] | M. Zeleny, Multiple criteria decision making., 1982. |

[46]

in their work. Considering the uncertainty of human preferences, the application of fuzzy logic is recommended in MCDM

hence the choice of the VIKOR fuzzy method. The different steps of the VIKOR fuzzy method are presented below.

Step 1: Having obtained the weights of the criteria and the fuzzy scores of the alternatives with respect to each criterion, we can now express the fuzzy multi-criteria decision-making problem in matrix form as follows.

(18)

Where the score of Alternative Ai in relation to criterion j (ie Cj) and wj denotes the importance weight of Cj

Step 2: It consists of determining the best fuzzy value (FBV;)and the worst fuzzy value (FWV;)of each criterion function, with i= 1, 2, …, n.

According to the following equations, the function can represent a benefit or a cost.

, and the geometric mean for mi can be used as average operators

| [47] | J. Vanícek, I. Vrana and S. Aly, "Fuzzy Aggregation and Averaging for Group Decision Making: A Generalization and Survey. Knowl.," Knowl Based Syst., vol. 22, pp. 79-84, 2009. https://doi.org/10.1016/j.knosys.2008.07.002 |

[47]

.

and(20)

and(21)

Step 3:It consists of calculating the values of the reflected fuzzy sum and the maximum of the fuzzy operators thanks to a reflected normalization (and defuzzification) of the distance according to the following equations where wj represents the weights of the criteria according to the preference of the DM (Marker decision).

(22)

(23)

(24)

Step 4. We determine the values S*, S−, R*, R−, from Sj and Rj of the alternatives,

(25)

(26)

Step 5. Let's calculate the fuzzy merit values for each alternative using equation (

31):

(27)

Where υ is the strategic weight of the majority of criteria or the maximum utility of the group, while (1− υ) is the weight of individual regret, with 0.7> υ >0.3. For υ =0.5, prioritization is not declared, because preferences for maximum benefit are taken into account when υ >0.5; and those of minimum regret when υ <0.5

Step 6. It consists of defuzzifying the values Sj, Rj, and Qj for each alternative by the following equations:

,

Step 7. It consists of choosing the compromised solution which is the alternative with the lowest Qj among all the other alternatives.

3.4. Proposed Methodology

The use of a MCDM (Multi-Criteria Decision Support) method makes it possible to evaluate and prioritize the different criteria according to their relative importance, in order to choose the micro hydraulic turbine technology best suited to the project. The proposed methodology combines three MCDM methods in three fundamental steps:

1. Identification and evaluation of criteria and alternatives: A group work session is organized to determine the possible technological alternatives and to evaluate the relevant criteria for decision-making. The purpose of this step is to validate the hierarchical structure of the decision-making process.

2. Assigning weights to criteria: The FAHP (Analytic Hierarchy Process) method is used to assign weights to the different criteria according to their relative importance.

3. Evaluation and ranking of alternatives: The F-TOPSIS and F-VIKOR methods are used to evaluate technological alternatives and rank them according to their performance against weighted criteria.

For this study, the evaluation criteria for micro-hydro turbines and PATs were identified through a review of relevant literature

| [16] | G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022. https://dx.doi.org/10.3390/en15197383 |

| [17] | S. Williamson, B. Stark and J. Booker, "Low Head Pico Hydro Turbine Selection Using a Multi-Criteria Analysis.," Renew. Energy, vol. 61, pp. 43–50, 2014. https://doi.org/10.1016/j.renene.2012.06.020 |

| [25] | A. Elbatran, O. Yaakob, A. Y. M. and H. Shabara, "Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review," Renewable and Sustainable Energy Reviews, vol. 43, pp. 40-50, 2015. http://dx.doi.org/10.1016/j.rser.2014.11.045 |

| [48] | C. S. Kaunda, C. Z. Kimambo and T. K. Nielsen, "technical discussion on microhydropower technology and its turbines," Renewable and Sustainable Energy Reviews, vol. 35, pp. 445-459, 2014. https://doi.org/10.1016/j.rser.2014.04.035 |

[16, 17, 25, 48]

and in collaboration with sector experts from the Water, Energy, and Environment laboratory at the Polytechnic of Yaoundé and the Hydroelectricity Association of Cameroon. These experts validated the selected criteria based on their feasibility and practicality within the project context. The technology acquisition criterion falls under economic criteria, while environmental impact is considered a social criterion. Technological criteria encompass the performance of the technology and the coupling of the turbine to the alternator. We included the turbine acquisition method and the type of alternator connection in our analysis, as these criteria are often overlooked in the literature. The characteristics of the environment and the location of most potential sites (pico and micro hydroelectricity) in the mountainous terrain of western Cameroon led us to limit our analysis to five alternatives from the diverse range of known hydraulic turbines: A1: Pelton Turbine (PT), A2: Banki or Crossflow Turbine (BT), A3: Turgo Turbine (TT), A4: Pump as Turbines (PAT), A5: Archimedes Screw (AS). The evaluation criteria comprise seven influence criteria, consisting of fourteen sub-criteria, used in the evaluation process. The table below presents the various criteria and sub-criteria selected for our study.

Table 2. Criteria and sub-criteria.

Criteria | Under criteria | Descriptions | Designations |

Acquisition of technology | Local manufacturing | Financial and material expenses related to the local manufacture of the turbine | C1 |

Import | Ease and speed for technology accessibility | C2 |

Technical parameters | Variation in fall height | The turbine chosen must be able to adapt to flow variations and have a higher probability of operating when flow is reduced | C3 |

Flow rate variation | The turbine chosen must be able to adapt to flow variations and have a higher probability of operating when flow is reduced | C4 |

Technology performance | Hydraulic efficiency | Efficiency of conversion of hydraulic energy into mechanical energy. | C5 |

Reliability | Probability that the turbine will operate without failure for a given period. | C6 |

Ease of installation and operation | Ease of installation | Complexity level of turbine installation | C7 |

Ease of operation | Level of complexity of turbine operation and maintenance. | C8 |

Maintenance Requirements | Preventive and corrective maintenance needs. | C9 |

Coupling the turbine to the alternator | Direct coupling | The alternator is mounted directly on the turbine shaft | C10 |

Speed Multiplier | A speed multiplier is used to increase the rotation speed of the turbine before sending it to the alternator. | C11 |

Turbine maintainability | Cost of maintenance | The maintenance cost depends on the type of turbine and its location. | C12 |

Technology Downtime | The turbine may be subject to regular maintenance checks by an on-site operator, or it may need to be operated remotely and therefore require downtime. | C13 |

Environment | Negative impact on the environment. | | C14 |

The figure below is the schematic diagram of the proposed methodology for selecting the appropriate micro hydraulic turbine technology for our study.

Figure 5. Schematic diagram of the proposed methodology for turbine selection.

4. Results and Discussions: Cameroon Case Study

The proposed methodology is applied to the Mfu River, located near the village of Mamfu in western Cameroon. We utilize this methodology for selecting a micro-hydro turbine to conduct a feasibility study for the implementation of a run-of-river micro-hydroelectric power plant at this site. The aim is to provide access to electricity for the local population. The site's characteristics and pictures are as follows:

Latitude: 5.0,6605° or 5° 39' 51" North, Longitude: 10,83804° or 10° 50' 17" East, Altitude: 1122 meters (3681 feet), Head: 30 m and Water Flow: 0.428 m3/S.

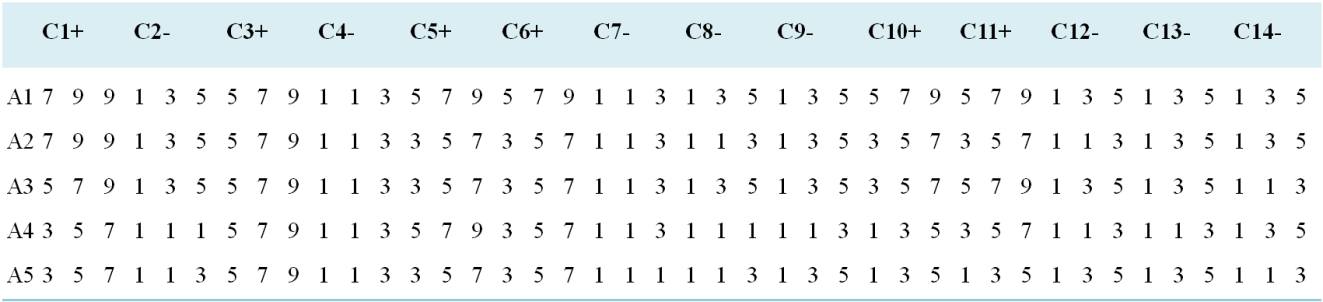

The subsequent sections will detail each phase and step of the proposed conceptual framework. Following a questionnaire sent to pico and micro-turbine manufacturers and micro-hydroelectricity experts (see Appendix 1), we obtained a decision matrix based on pairwise comparisons expressed in triangular fuzzy numbers to apply the FAHP method for determining the weights of the criteria. This matrix is presented below.

Table 3. Pairwise comparison matrix developed using the Fuzzy AHP method for the fourteen (14) criteria.

| C1 | C2 | C3 | C4 | C5 | C6 | C7 |

C1 | (1,1,1) | (5,7,9) | (1,3,5) | (0.2,0.33,1) | (0.14,0.2,0.33) | (3,5,7) | (1,3,5) |

C2 | (0.11,0.14,0.2) | (1,1,1) | (3,5,7) | (3,5,7) | (5,7,9) | (5,7,9) | (0.2,0.33,1) |

C3 | (0.2,0.33,1) | (0.14,0.2,0.33) | (1,1,1) | (3,5,7) | (3,5,7) | (5,7,9) | (0.11,0.14,0.2) |

C4 | (1,3,5) | (0.14,0.2,0.33) | (0.14,0.2,0.33) | (1,1,1) | (0.14,0.2,0.33) | (0.14,0.2,0.33) | (5,7,9) |

C5 | (3,5,7) | (0.11,0.14,0.2) | (0.14,0.2,0.33) | (3,5,7) | (1,1,1) | (5,7,9) | (0.14,0.2,0.33) |

C6 | (0.14,0.2,0.33) | (0.11,0.14,0.2) | (0.11,0.14,0.2) | (3,5,7) | (0.11,0.14,0.5) | (1,1,1) | (1,3,5) |

C7 | (0.2,0.33,1) | (1,3,5) | (5,7,9) | (0.11,0.14,0.2) | (3,5,7) | (0.2,0.33,1) | (1,1,1) |

C8 | (3,5,7) | (1,3,5) | (5,7,9) | (0.11,0.14,0.2) | (3,5,7) | (0.14,0.2,0.33) | (5,7,9) |

C9 | (0.14,0.2,0.33) | (0.14,0.2,0.33) | (5,7,9) | (0.11,0.14,0.2) | (3,5,7) | (0.14,0.2,0.33) | (5,7,9) |

C10 | (1,1,3) | (0.14,0.2,0.33) | (1,3,5) | (3,5,7) | (0.11,0.14,0.2) | (0.14,0.2,0.33) | (0.14,0.2,0.33) |

C11 | (1,1,3) | (1,1,3) | (1,3,5) | (3,5,7) | (0.11,0.14,0.2) | (0.2,0.33,1) | (0.14,0.2,0.33) |

C12 | (0.2,0.33,1) | (1,1,3) | (0.33,1,1) | (1,3,5) | (1,3,5) | (0.2,0.33,1) | (1,3,5) |

C13 | (0.2,0.33,1) | (5,7,9) | (0.33,1,1) | (1,1,3) | (1,3,5) | (1,1,3) | (1,3,5) |

C14 | (1,3,5) | (5,7,9) | (1,1,1) | (0.33,1,1) | (1,3,5) | (1,1,3) | (0.11,0.14,0.2) |

| C8 | C9 | C10 | C11 | C12 | C13 | C14 |

C1 | (0.14,0.2,0.33) | (3,5,7) | (0.33,1,1) | (0.33,1,1) | (1,3,5) | (1,3,5) | (0.2,0.33,1) |

C2 | (0.2,0.33,1) | (3,5,7) | (3,5,7) | (0.33,1,1) | (0.33,1,1 | (0.11,0.14,0.2 | (0.11,0.14,0.2) |

C3 | (0.11,0.14,0.2) | (0.11,0.14,0.2) | (0.2,0.33,1) | (0.2,0.33,1 | (1,1,3) | (1,1,3) | (1,1,1) |

C4 | (5,7,9) | (5,7,9) | (0.14,0.2,0.33) | (0.14,0.2,0.33) | (0.2,0.33,1) | (0.33,1,1) | (1,1,3) |

C5 | (0.14,0.2,0.33) | (0.14,0.2,0.33) | (5,7,9) | (5,7,9) | (0.2,0.33,1) | (0.2,0.33,1) | (0.2,0.33,1) |

C6 | (3,5,7) | (3,5,7) | (3,5,7) | (3,5,7) | (1,3,5) | (0.33,1,1) | (0.33,1,1) |

C7 | (0.11,0.14,0.2) | (0.11,0.14,0.2) | (3,5,7) | (3,5,7) | (0.2,0.33,1) | (0.2,0.33,1) | (5,7,9) |

C8 | (1,1,1) | (5,7,9) | (0.14,0.2,0.33) | (0.14,0.2,0.33) | (1,3,5) | (0.33,1,1) | (0.33,1,1) |

C9 | (0.11,0.14,0.2) | (1,1,1) | (5,7,9) | (5,7,9) | (1,3,5) | (1,3,5) | (1,1,3) |

C10 | (3,5,7) | (0.11,0.14,0.2) | (1,1,1) | (1,1,3) | (1,3,5) | (0.33,1,1) | (0.33,1,1) |

C11 | (3,5,7) | (0.11,0.14,0.2) | (0.33,1,1) | (1,1,1) | (02,0.33,1) | (1,1,3) | (1,3,5) |

C12 | (0.2,0.33,1) | (0.2,0.33,1) | (0.2,0.33,1) | (1,3,5) | (1,1,1) | (1,3,5) | (0.2,0.33,1) |

C13 | (1,1,3) | (0.2,0.33,1) | (1,1,3) | (0.33,1,1) | (0.2,0.33,1) | (1,1,1) | (0.2,0.33,1) |

C14 | (1,1,3) | (1,1,3) | (1,1,3) | (0.2,0.33,1) | (1,3,5) | (1,3,5) | (1,1,1) |

Equation

1 is used to obtain

Table 3 below.

Table 4. Results of triangular fuzzy numbers of ri.

Criteria | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 |

ri | l | 0.672 | 0.727 | 0.503 | 0.500 | 0.569 | 0.684 | 0.626 | 0.790 |

m | 1.342 | 1.171 | 0.667 | 0.760 | 0.826 | 1.215 | 0.963 | 1.375 |

r | 2.088 | 1,690 | 1.182 | 1.208 | 1,373 | 1,650 | 1,650 | 1,870 |

Criteria | C9 | C10 | C11 | C12 | C13 | C14 | total | Reverse |

ri | l | 0.820 | 0.478 | 0.544 | 0.463 | 0.604 | 0.789 | 8,774 | 0.0425 |

m | 1.224 | 0.787 | 0.845 | 0.920 | 0.979 | 1.262 | 14,343 | 0.06972 |

r | 1,836 | 1.218 | 1,543 | 1,921 | 2.015 | 2.260 | 23,509 | 0.113964 |

To obtain the fussy weight we used equation

2, the results are represented in the following table:

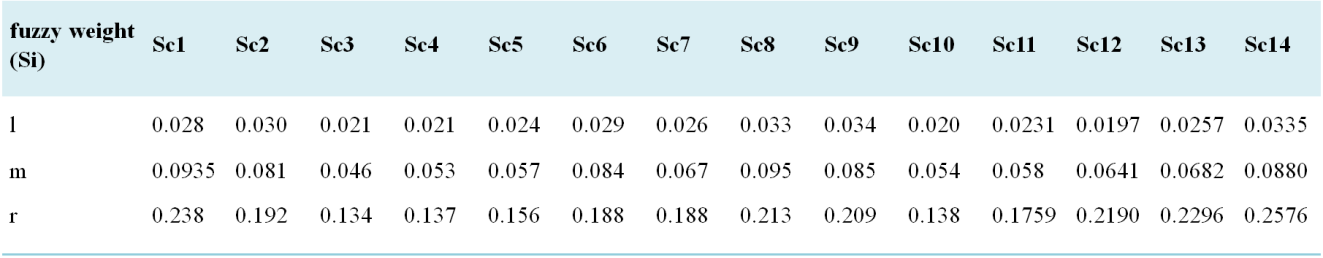

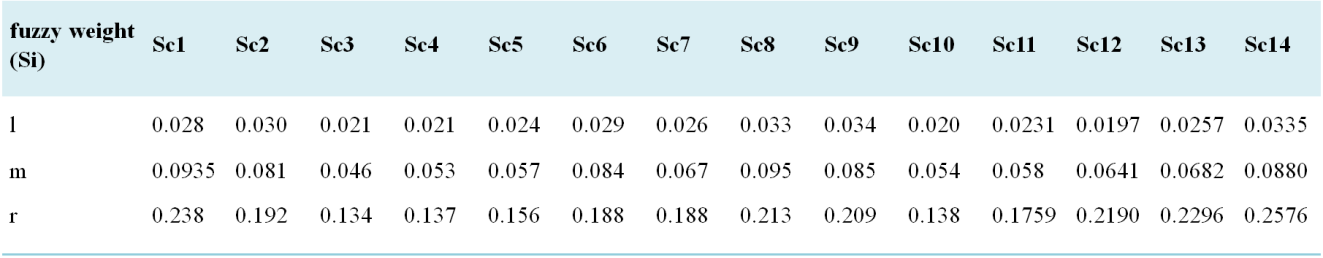

Table 5. Values of the fuzzy weights.

To obtain the local weight and global weight we used equations

3 and

4.

Figure 7. Chart of the global weight and rank of 14 criteria.

Environmental Impact (C14) is the most important criterion: It has the highest global weight and is ranked first. Local Manufacturing (C1) is the second most important criterion: It has the second highest global weight and is ranked second. Other criteria have varying levels of importance: The remaining criteria have lower global weights and are ranked accordingly. The study prioritizes sustainability and community involvement. Environmental impact is considered a critical factor in the decision-making process. Local manufacturing is seen as a key driver of economic development and job creation.

By providing more context, we can better interpret the significance of these results.

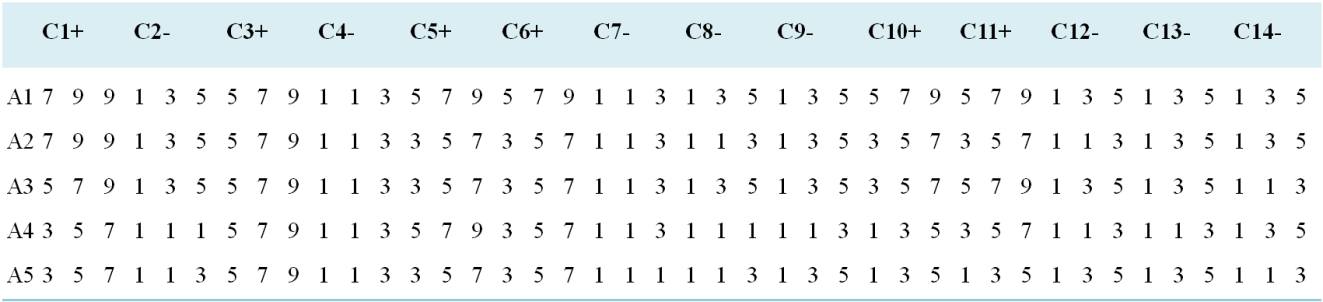

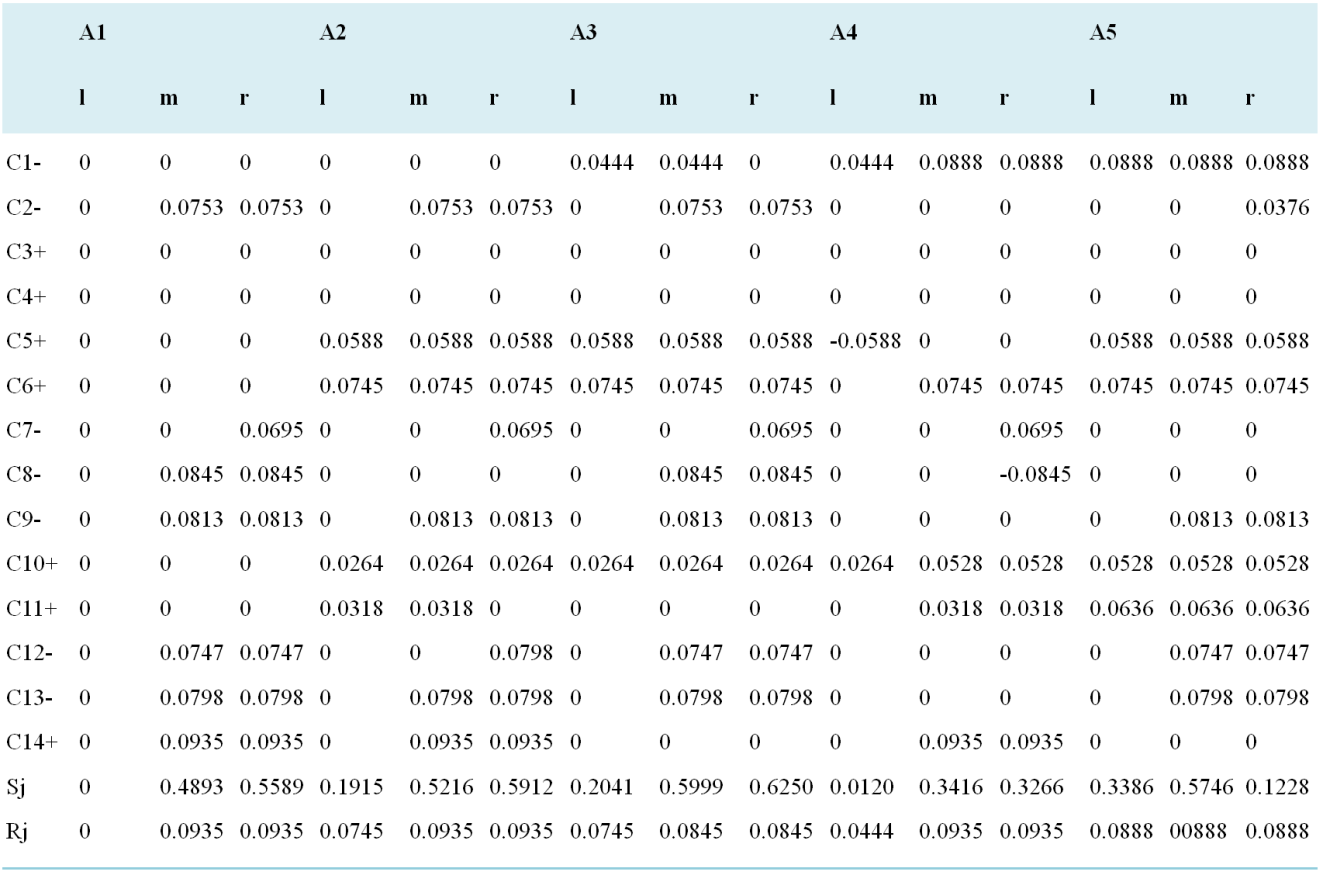

After having determined the weight of the criteria with the FAHP method, we will apply the fussy TOPSIS technique to find the best alternative among the selected alternatives. Thus, the following Table is the result of the compilation of five opinions of experts in the field, it is the fuzzy decision matrix.

Table 6. Fuzzy matrix resulting from five expert opinions.

We will use equations

10 and

11 to determine the fuzzy evaluation matrix.

Table 7. Result of the fuzzy matrix.

| C1+ | C2- | C3+ | C4- | C5+ |

A1 | 0.7777 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.5555 | 0.7777 | 1 | 0.3333 | 1 | 1 | 0.5555 | 0.7777 | 1 |

A2 | 0.7777 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.5555 | 0.7777 | 1 | 0.3333 | 1 | 1 | 0.3333 | 0.5555 | 0.7777 |

A3 | 0.5555 | 0.7777 | 1 | 0.2 | 0.3333 | 1 | 0.5555 | 0.7777 | 1 | 0.3333 | 1 | 1 | 0.3333 | 0.5555 | 0.7777 |

A4 | 0.3333 | 0.5555 | 0.7777 | 1 | 1 | 1 | 0.5555 | 0.7777 | 1 | 0.3333 | 1 | 1 | 0.5555 | 0.7777 | 1 |

A5 | 0.3333 | 0.5555 | 0.7777 | 0.3333 | 1 | 1 | 0.5555 | 0.7777 | 1 | 0.3333 | 1 | 1 | 0.3333 | 0.5555 | 0.7777 |

Weight | 0.0889 | 0.0753 | 0.05 | 0.0523 | 0.0588 |

| C6+ | C7- | C8- | C9- | C10+ |

A1 | 0.5555 | 0.7777 | 1 | 0.3333 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 | 0.5555 | 0.7777 | 1 |

A2 | 0.3333 | 0.5555 | 0.7777 | 0.3333 | 1 | 1 | 0.3333 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.3333 | 0.5555 | 0.7777 |

A3 | 0.3333 | 0.5555 | 0.7777 | 0.3333 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 | 0.3333 | 0.5555 | 0.7777 |

A4 | 0.3333 | 0.5555 | 0.7777 | 0.3333 | 1 | 1 | 1 | 1 | 1 | 0.3333 | 1 | 1 | 0.1111 | 0.3333 | 0.5555 |

A5 | 0.3333 | 0.5555 | 0.7777 | 1 | 1 | 1 | 0.3333 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.1111 | 0.3333 | 0.5555 |

Weight | 0.0745 | 0.0696 | 0.0846 | 0.0813 | 0.0528 |

| C11+ | C12+ | C13- | C14- |

A1 | 0.5555 | 0.7777 | 1 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 |

A2 | 0.3333 | 0.5555 | 0.7777 | 0.3333 | 1 | 1 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 |

A3 | 0.5555 | 0.7777 | 1 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 | 0.3333 | 1 | 1 |

A4 | 0.3333 | 0.5555 | 0.7777 | 0.333 | 1 | 1 | 0.3333 | 1 | 1 | 0.2 | 0.3333 | 1 |

A5 | 0.1111 | 0.3333 | 0 | 0.2 | 0.3333 | 1 | 0.2 | 0.3333 | 1 | 0.3333 | 1 | 1 |

Weight | 0.0637 | 0.0747 | 0.0799 | 0.0936 |

Using the weights of the criteria calculated by FAHP (

Table 6) we will determine the weighted evaluation matrix using equations

12, 13 and equations

14, 15 to determine d+ and d-.

By applying equations

16 and

17, we determine the distance between two TFNXs and the proximity coefficient of each alternative in order to make the classification.

Figure 8. Chart of the results of fuzzy TOPSIS analysis.

A4 has the largest cc (0.554652), indicating a good compromise between the criteria. We find that the PAT has the largest proximity coefficient, so it is the best alternative, followed by the Pelton turbine.

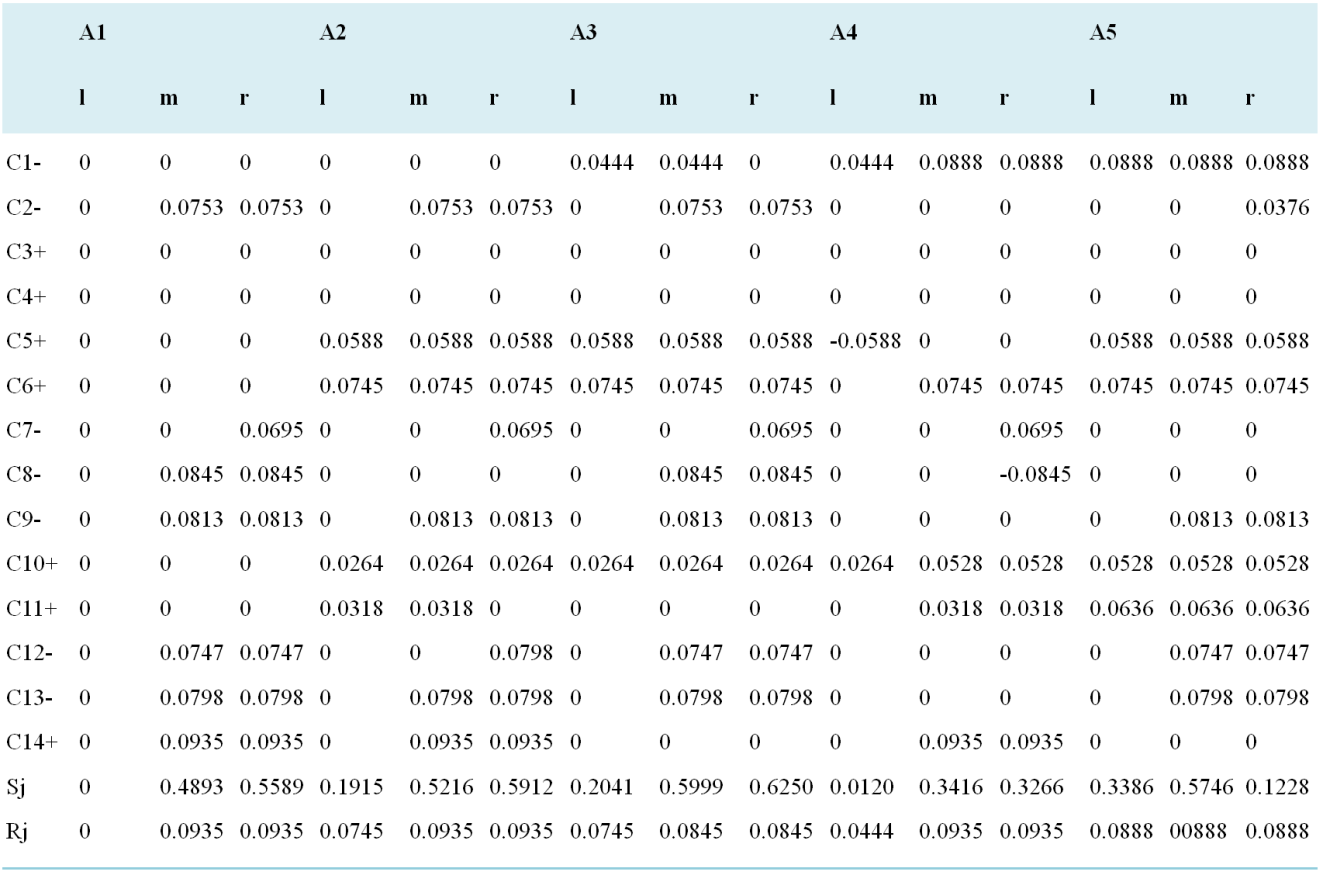

After using the Fussy TOPSIS method we move on to the Fussy VIKOR method to also propose a ranking of the alternatives selected for the best micro hydraulic turbine in order to make a choice that will suit our case. The standardized decision matrix used is the same as that of the TOPSIS methodology,

Table 7.

Using equations

18 and

19 we will obtain the best fuzzy values and the worst fuzzy values of the criteria. After this we are using 20,21 and 22 with the weights determined by the FAHP method, we obtained the table below.

Table 8. Result of the values of the reflected fuzzy sum and the maximum of the fuzzy operators. .

Subsequently using equations

25 and

26 and obtain the following table.

Table 9. Fuzzy result of R*, R-, S*, S-.

| l | m | r |

S* | 0 | 0.341632 | 0.326648 |

S- | 0.338698 | 0.599967 | 0.625097 |

R* | 0 | 0.084553 | 0.084553 |

R- | 0.08888 | 0.093584 | 0.093584 |

Using equations

27 and

30 we will determine Q

f of the different alternatives and classify them in order.

Figure 9. Chart of the results of fuzzy VIKOR analysis.

By applying the Fussy VIKOR method, the A5 and A1 turbines were found as compromised solutions for all scenarios taking into account the strategic weightings (v=0.5). Therefore, the PAT is considered the best followed by the Pelton turbine for our study according to the 14 criteria taken into account.

Comparison of results:

Both methods come to the same conclusion about the best performing alternative: A4. TOPSIS fuzzy (

figure 8): A4 has the largest cc (0.554652), indicating a good compromise between the criteria. And with VIKOR fuzzy (

figure 9): A4 having (the smallest Q

f) is therefore considered the best alternative.

The choice of the multi-criteria optimization methods used, MCDM or MCDA, does not automatically affect the rankings of the alternatives. The data used for the criteria are values assigned by experts and that can vary from one expert to another, which is why in our work we used the compilation of data provided by five experts in the field and turbine manufacturer as done in the article

| [16] | G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022. https://dx.doi.org/10.3390/en15197383 |

[16]

. Thus, when comparing the results of the two Fussy MCDM methods used in our study for ranking, alternative A4 (PAT) always occupies the first position and alternative A1 (Pelton turbine) occupies the second position. The fact that both methods reach the same conclusion on the best alternative A4 (PAT) strengthens confidence in the results. However, when we use the technical parameters of our site using the turbine selection nomogram in

Figure 3 and calculating the hydraulic power by applying Equation

2, we see that the Pelton, Banki and Turgo turbines are the ones that correspond to our site. This proposed methodology has therefore allowed us to make a more refined choice on the five pre-selected turbines in order to choose the most suitable one by involving several factors by only the technical factors concerning our site. Thus, we can support the consistency of the result of our methodology by some research works that justify the choice of PAT turbines as an ideal solution for the exploitation of micro hydroelectricity potentials

| [8] | A. Asad, Y. Jianping and H. Javed, "Small hydropower generation using pump as turbine; a smart solution for the development of Pakistan’s energy," Heliyon, vol. 9, pp. 1-16, 2023. https://doi.org/10.1016/j.egypro.2017.11.042 |

| [49] | D. Adu, Z. Jinfeng, F. Yujian, Ransford.O. and D. L. Suomingb, "A Case Study of Status and Potential of Small Hydro-Power Plants in Southern African Development Community," th International Conference on Power and Energy Systems Engineering, CPESE 2017, 25-29, vol. 141, pp. 352-359, 25-29 september 2017. https://doi.org/10.1016/j.egypro.2017.11.042 |

[8, 49]

and

also Pelton turbines compared to other impulse turbines. This is the case of

| [24] | M. A. S, M. B. C. Cherchia and M. Swindleb, "Recent innovations and trends in in-conduit hydropower technologies and their applications in water distribution systems," Journal of Environmental Management, vol. 228, pp. 416–428, 2018. https://doi.org/10.1016/j.jenvman.2018.08.078 |

[24]

and

| [51] | B. H. S. a. J. D. B. S. J. Williamson, "“Low head pico hydro turbine selection using a multi-criteria analysis," Renew. Energy, vol. 61, pp. 43–50, 2014. |

[51]

show that Pelton turbines have the advantage over other turbines of being best suited for low flow rate electricity production and highly suited for low heads.

, in his work justifies the choice of the Pelton turbine for the installation of a micro-power plant due to its advantage of using light materials and local availability for its low-cost manufacturing, with an appreciable surface finishing capacity and mechanical and physical specifications necessary for a prolonged service life, possessing a natural capacity for resistance to corrosion.

The socio-economic benefits of the study

The electrification of a country or locality is one of the main determining factors for its economic growth.

| [53] | A. Gurun, I. Bryceson, J. H. Joo and S.-E. Oh, "Socio-economic impacts of a micro-hydropower plant on rural livelihoods," Scientific Research and Essays, vol. 6, no. 19, pp. 3964-3972, 2011. https://doi.org/10.5897/SRE10.766 |

[53]

presents the socio-economic advantages of a micro-hydropower plant in rural areas.

| [54] | Y. Mitsumori, "Socio-economic Impact of Small Hydropower on community: A new local electricity biz in Kyushu to bring benefit to local community," in 9th International Congress on Advanced Applied Informatics (IIAI-AAI), 2020. https://doi.org/10.1109/IIAI-AAI50415.2020.00127 |

[54]

also demonstrates the socio-economic benefits of utilizing micro-hydroelectricity for improving the living conditions of the rural population. Given that the rural electrification rate in Cameroon is around 21%, according to the Minister in charge of Water and Energy, despite the government's efforts to meet the population's demand, the use of this methodological approach by local experts in the field for the selection of micro hydraulic turbine technology will be useful for the low-cost local manufacturing of micro-turbines. This will also facilitate the implementation of pico or micro-hydropower plants in villages or remote areas where we have hydroelectric potential. This approach is designed to enhance local expertise, with the aim of harnessing our hydroelectric potential and using locally available materials for the local manufacturing of micro-hydraulic turbines. Above all, it will address the problem of rural population electrification by giving them access to electricity to improve their living conditions in terms of health, education, transportation, and their overall development.

5. Conclusion

The choice of the type of hydraulic turbine is very complex and cannot be a global study for several sites, since the typology of the latter varies depending on the site and the technical parameters available. The fuzzy MCDM approach consisting of the fuzzy AHP, fuzzy TOPSIS and fuzzy VIKOR methods, allowed us to take into account the inherent uncertainties and subjectivity in order to propose a methodology for the selection of an appropriate micro hydraulic turbine technology, taking into account acquisition, performance, maintainability, coupling and environmental criteria. The analysis revealed that the PAT technology is the best option among the five alternatives proposed for our potential site, taking into account the specific conditions of the site and the objectives of the study which is to have a locally accessible and easily exploitable technology. This technology offers a good compromise compared to the Pelton turbine and other turbines. This result can also be justified by the efficiency, flexibility, good control of speed and flow offered by PATs, and especially the ease of maintenance compared to traditional turbines. Thus, this study has contributed to demonstrating the potential of fuzzy MCDM methods for decision-making in the field of renewable energy in Cameroon. The use of these tools will ensure an informed selection of technologies, thus contributing to the sustainable development of the country.

Recommendations for future research:

1. Extend the application of fuzzy MCDM to other micro-hydroelectric projects in different regions of Cameroon and Africa.

2. Develop computer tools to automate the decision-making process and facilitate the use of fuzzy MCDM methods.

Abbreviations

MCDM | Multiple Criteria Decision Making |

IEA | International Energy Agency |

AHP | Analytical Hierarchy Process |

F-TOPSIS | A Picky Technique for Order Preference by Similarity to the Ideal Solution |

F-VIKOR | Fussy Aims to Optimize Performance |

PAT | Pump as Turbine |

FAHP | Analytical Hierarchy Process |

ELECTRA | Elimination and Choice Reflecting Reality |

SSA | Sub-Saharan Africa |

COVID-19 | Corona Virus Disease- 19 |

RES | Renewable Energy Sources |

GHG | Greenhouse Gas |

GW | Gigawatt |

SHP | Small Hydroelectric Power Plants |

TFNs | Triangular Fussy Numbers |

Author Contributions

Haoua Laila Tidjani: Conceptualization, Formal Analysis, Investigation, Methodology, Resources, Software, Writing – original draft, Writing – review & editing

Joseph Kenfack: Project administration, Supervision, Validation, Writing – review & editing

Oumarou Hamandjoda: Project administration, Supervision, Validation

Mbitekamboh Richard Wankie: Methodology, Software, Writing – original draft, Writing – review & editing

Matho Raissa Mekjele: Methodology, Software, Writing – original draft, Writing – review & editing

Nsangou Jean Calvin: Methodology, Software, Writing – original draft, Writing – review & editing

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix

Questionnaire to bring out the pairwise comparison matrix

This questionnaire is designed to bring out the pairwise comparison matrix to determine the weights of each criterion using the FAHP method for use in the fuzzy TOPSIS and fuzzy VIKOR methods to select the best alternative for the project.

Thus, please read the following questions and give values on the pairwise comparison matrix below. These questions are designed to assess various attributes in pairs based on your experience. We use the fuzzy triangular importance scale table below for the construction of the comparison matrix.

Table A1. The fuzzy triangular linguistic importance scale.

Linguistic scale | TFN Scale | Reciprocal scale of TFNs |

Very weak | (1,1,1) | (1,1,1) |

Weak | (1,1,3) | (1/3,1,1) |

Moderately poor | (1,3,5) | (5/2.1/3.1) |

Average | (3,5,7) | (1/7,1/5,1/3) |

Moderately high | (5,7,9) | (1/9,1/7,1/5) |

High | (7,9,9) | (1/9,1/9,1/7) |

Compared to local manufacturing (C1).

Q1. How important is local manufacturing (C1) when compared to importing (C2)?

Q2. How important is local manufacturing (C1) when compared to drop height variation (C3)?

Q3. How important is local manufacturing (C1) when compared to flow variation (C4)?

Q4. How important is local manufacturing (C1) when compared to hydraulic efficiency (C5)?

Q5. How important is local manufacturing (C1) when compared to reliability (C6)?

Q6. How important is local manufacturing (C1) when compared to ease of installation (C7)?

Q7. How important is local manufacturing (C1) when compared to ease of operation (C8)?

Q8. How important is local manufacturing (C1) when compared to maintenance requirements (C9)?

Q9. How important is local manufacturing (C1) when compared to direct coupling (C10)?

Q10. How important is local manufacturing (C1) when compared to speed multiplier (C11)?

Q11. How important is local manufacturing (C1) when compared to the cost of maintenance (C12)?

Q12. How important is local manufacturing (C1) when compared to technology downtime (C13)?

Q13. How important is local manufacturing (C1) when compared to the negative impact on the environment. (C13)?

Compared to import (C2).

Q1. How important is import (C2) when compared to drop height variation (C3)?

Q2. How important is import (C2) when compared to flow variation (C4)?

Q3. How important is import (C2) when compared to hydraulic efficiency (C5)?

Q4. How important is import (C2) when compared to reliability (C6)?

Q5. How important is import (C2) when compared to ease of installation (C7)?

Q6. How important is import (C2) when compared to ease of operation (C8)?

Q7. How important is import (C2) when compared to maintenance requirements (C9)?

Q8. How important is import (C2) when compared to direct coupling (C10)?

Q9. How important is import (C2) when compared to speed multiplier (C11)?

Q10. How important is import (C2) when compared to maintenance cost (C12)?

Q11. How important is import (C2) when compared to technology downtime (C13)?

Q12. How significant is the import (C2) when compared to the negative impact on the environment. (C14)?

Compared to the variation in fall height (C3).

Q1. How significant is the variation in head (C3) when compared to the variation in flow (C4)?

Q2. How significant is the variation in head (C3) when compared to hydraulic efficiency (C5)?

Q3. How important is the variation in drop height (C3) when compared to reliability (C6)?

Q4. How important is the variation in drop height (C3) when compared to ease of installation (C7)?

Q5. How significant is the variation in drop height (C3) when compared to ease of operation (C8)?

Q6. How significant is the drop height variation (C3) when compared to the maintenance requirements (C9)?

Q7. How significant is the drop height variation (C3) when compared to direct coupling (C10)?

Q8. How significant is the drop height variation (C3) when compared to the speed multiplier (C11)?

Q9. How significant is the variation in drop height (C3) when compared to the cost of maintenance (C12)?

Q10. How significant is the drop height variation (C3) when compared to the technology downtime (C13)?

Q11. How significant is the change in fall height (C3) when compared to the negative impact on the environment. (C14)?

Compared to the flow variation (C4)

Q1. How significant is the variation in head (C3) when compared to hydraulic efficiency (C5)?

Q2. How important is flow variation (C4) when compared to reliability (C6)?

Q3. How important is flow variation (C4) when compared to ease of installation (C7)?

Q4. How important is flow variation (C4) when compared to ease of operation (C8)?

Q5. How significant is the flow variation (C4) when compared to the maintenance requirements (C9)?

Q6. How significant is the flow variation (C4) when compared to direct coupling (C10)?

Q7. How significant is the flow rate variation (C4) when compared to the speed multiplier (C11)?

Q8. How significant is the flow rate variation (C4) when compared to the maintenance cost (C12)?

Q9. How significant is the flow variation (C4) when compared to the technology downtime (C13)?

Q10. How significant is the flow variation (C4) when compared to the negative environmental impact (C14)?

Compared to hydraulic efficiency (C5)

Q1. How important is hydraulic efficiency (C5) when compared to reliability (C6)?

Q2. How important is hydraulic efficiency (C5) when compared to ease of installation (C7)?

Q3. How important is hydraulic efficiency (C5) when compared to ease of operation (C8)?

Q4. How important is hydraulic efficiency (C5) when compared to maintenance requirements (C9)?

Q5. How important is hydraulic efficiency (C5) when compared to direct coupling (C10)?

Q6. How important is hydraulic efficiency (C5) when compared to speed multiplier (C11)?

Q7. How important is hydraulic efficiency (C5) when compared to maintenance cost (C12)?

Q8. How important is hydraulic efficiency (C5) when compared to technology downtime (C13)?

Q9. How significant is the flow variation (C4) when compared to the negative environmental impact (C14)?

Compared to reliability (C6)

Q1. How important is reliability (C6) when compared to ease of installation (C7)?

Q2. How important is reliability (C6) when compared to ease of operation (C8)?

Q3. How important is reliability (C6) when compared to maintenance requirements (C9)?

Q4. How important is reliability (C6) when compared to direct coupling (C10)?

Q5. How important is reliability (C6) when compared to speed multiplier (C11)?

Q6. How important is reliability (C6) when compared to maintenance cost (C12)?

Q7. How important is reliability (C6) when compared to technology downtime (C13)?

Q8. How important is reliability (C6) when compared to negative environmental impact (C14)?

Compared to ease of installation (C7)

Q1. How important is ease of installation (C7) when compared to ease of operation (C8)?

Q2. How important is ease of installation (C7) when compared to maintenance requirements (C9)?

Q3. How important is ease of installation (C7) when compared to direct coupling (C10)?

Q4. How important is ease of installation (C7) when compared to speed multiplier (C11)?

Q5. How important is ease of installation (C7) when compared to cost of maintenance (C12)?

Q6. How important is ease of installation (C7) when compared to technology downtime (C13)?

Q7. How important is ease of installation (C7) when compared to negative environmental impact (C14)?

Compared to ease of operation (C8)

Q1. How important is ease of operation (C8) when compared to maintenance requirements (C9)?

Q2. How important is ease of operation (C8) when compared to direct coupling (C10)?

Q3. How important is ease of operation (C8) when compared to speed multiplier (C11)?

Q4. How important is ease of operation (C8) when compared to cost of maintenance (C12)?

Q5. How important is ease of operation (C8) when compared to technology downtime (C13)?

Q6. How important is ease of operation (C8) when compared to negative environmental impact (C14)?

In relation to maintenance requirements (C9)

Q1. How important is the maintenance requirement (C9) when compared to direct coupling (C10)?

Q2. How important is the maintenance requirement (C9) when compared to the speed multiplier (C11)?

Q3. How important is the maintenance requirement (C9) when compared to the cost of maintenance (C12)?

Q4. How important is maintenance requirement (C9) when compared to technology downtime (C13)?

Q5. How important are maintenance requirements (C9) when compared to negative environmental impact (C14)?

Compared to direct coupling (C10)

Q1. What is the importance of direct coupling (C10) when compared to speed multiplier (C11)?

Q2. How important is direct coupling (C10) when compared to maintenance cost (C12)?

Q3. How important is direct coupling (C10) when compared to technology downtime (C13)?

Q4. How important is direct coupling (C10) when compared to negative environmental impact (C14)?

Compared to the speed multiplier (C11)

Q1. How important is the speed multiplier (C11) when compared to the maintenance cost (C12)?

Q2. How important is the speed multiplier (C11) when compared to the technology downtime (C13)?

Q3. How significant is the speed multiplier (C11) when compared to the negative environmental impact (C14)?

Compared to the cost of maintenance (C12)

Q1. How important is the cost of maintenance (C12) when compared to technology downtime (C13)?

Q2. How significant is the cost of maintenance (C12) when compared to the negative impact on the environment (C14)?

Compared to technology downtime (C13)

Q1. How important is the downtime of technology (C13) when compared to the negative impact on the environment (C14)?

References

| [1] |

A. Korkovelos, D. Mentis, S. Siyal and R. H, "A geospatial assessment of small-scale hydropower potential in sub-saharan," Energies, no. 111, pp. 1-21, 2018.

https://doi.org/10.3390/en11113100

|

| [2] |

Hugo LE PICARD, "Nouveau paradigme de l ’électrification en Afrique subsaharienne Comment les systèmes hybrides décentralisés changent-ils la donne ?’," l’Institut français des relations internationales (Ifri) et le Policy Center for the New South, FRANCE, 2022.

|

| [3] |

G. Dranka and G. Ferreir, "Planning for a Renewable Future in the Brazilian Power System," Energy, vol. 164, pp. 496–511, 2018.

https://doi.org/10.1016/j.energy.2018.08.164

|

| [4] |

I. H. Association, "Hydropower Status Report," IHA, London, UK, 2019.

|

| [5] |

H. L. Tidjani, M. M. Raïssa, K. Joseph, O. Hamandjoda and A. E. Patrice, "Selection of a Suitable Material by a Multi-Criteria Decision Aid Method (Mcdm) for the Manufacture of the Buckets of a Micro Pelton Turbine," American Journal of Energy and Natural Resources (AJENR), 2023.

https://doi.org/10.54536/ajenr.v2i1.1101

|

| [6] |

W. Rijsenbeek, "Pico hydro systems in Vietnam," rural energy supply models, 2001.

|

| [7] |

Williams A, "Pumps as turbines," a user’s guide. 2nd ed. London:ITDG, london, 2003.

|

| [8] |

A. Asad, Y. Jianping and H. Javed, "Small hydropower generation using pump as turbine; a smart solution for the development of Pakistan’s energy," Heliyon, vol. 9, pp. 1-16, 2023.

https://doi.org/10.1016/j.egypro.2017.11.042

|

| [9] |

A. A. Williams and R. Simpson, "Pico hydro - reducing technical risks for rural electrification," Renewable Energy, vol. 32, pp. 1986-1991, 2009.

https://doi.org/10.1016/j.renene.2008.12.011

|

| [10] |

C. Achebe, O. Okafor and E. Obika, "Design and implementation of a crossflow turbine for Pico hydropower electricity generation," Heliyon, vol. 6, pp. 1-13, 2020.

https://doi.org/10.1016/j.heliyon.2020.e04523

|

| [11] |

Y. Yildiz V, "Numerical Simulation Model of Run of River Hydropower Plants: Concepts, Numerical Modeling, Turbine System and Selection, and Design Optimization," University of California, Oakland, CA, USA, 2015.

https://escholarship.org/uc/item/0jb5v4df

|

| [12] |

S. Sangal, G. A. and D. Kumar, "Review of Optimal Selection of Turbines for Hydroelectric Projects.," Int. J. Emerg. Technol. Adv. Eng., vol. 3, pp. 424–430, 2013.

|

| [13] |

A. Adejumobi and D. Shobayo, "Optimal Selection of Hydraulic Turbines for Small Hydro Electric Power Generation—A Case Study of Opeki River, South Western Nigeria.," Niger. J. Technol., vol. 34, pp. 530-542, 2015.

http://dx.doi.org/10.4314/njt.v34i3.15.15

|

| [14] |

A. Williams and D. Upadhyay, "Low Head Pico Hydropower: A Review of Available Turbine Technologies.," In World Renewable Energy Congress VI (WREC2000), pp. 1745–1750, 2000.

https://doi.org/10.1016/B978-008043865-8/50306-8

|

| [15] |

M. Yenugula, S. Sahoo and S. Goswami, "Cloud computing in supply chain management: Exploring the relationship.," Management Science Letters, vol. 13, no. 3, pp. 193-210, 2023.

http://dx.doi.org/10.5267/j.msl.2023.4.003

|

| [16] |

G. G. D; D. S. a. P. F. Rudimar Caricimi, "Reframing the Selection of Hydraulic Turbines Integrating Analytical Hierarchy Process (AHP) and Fuzzy VIKOR Analytical Hierarchy Process (AHP) and Fuzzy VIKOR," energies, pp. 1-26, 2022.

https://dx.doi.org/10.3390/en15197383

|

| [17] |

S. Williamson, B. Stark and J. Booker, "Low Head Pico Hydro Turbine Selection Using a Multi-Criteria Analysis.," Renew. Energy, vol. 61, pp. 43–50, 2014.

https://doi.org/10.1016/j.renene.2012.06.020

|

| [18] |

C. Kahraman, G. Büyükzokan and N. Y. et Ates, "A two phase multi-attribute decision making approach for new product introduction.," Information Sciences,, vol. 177, pp. 1567–1582, 2007.

https://doi.org/10.1016/j.ins.2006.09.008

|

| [19] |

T. Boumedyen, "La méthode PROMETHEE comme outil d'aide à la décision multicritère," Revue Algérienne d’Economie et de Management, vol. 8, pp. 1-11, 2017.

|

| [20] |

S. S. Goswami and D. K. Behera, "Evaluation of the best smartphone model in the market by integrating fuzzy AHP and PROMETHEE decision-making approach. Decision," Decision, vol. 48, pp. 71-96, 2021.

https://doi.org/10.1007/s40622-020-00260-8

|

| [21] |

A. M. Pakdin, "Project selection for oil-fields development by using the AHP and fuzzy TOPSIS methods," Expert Systems with Applications, vol. 37, pp. 6218–6224, 2010.

https://doi.org/10.1016/j.eswa.2010.02.103

|

| [22] |

Y. Solangi, Q. Tan, N. Mirjat and S. Ali, "Evaluating the Strategies for Sustainable Energy Planning in Pakistan: An Integrated SWOT-AHP and Fuzzy-TOPSIS Approach.," Journal of Cleaner Production, vol. 236, pp. 1-14, 2019.

|

| [23] |

S. Opricovic, "Fuzzy VIKOR with an application to water resources planning," Expert Systems with Applications, vol. 38, p. 12983–12990, 2011.

https://doi.org/10.1016/j.eswa.2011.04.097

|

| [24] |

M. A. S, M. B. C. Cherchia and M. Swindleb, "Recent innovations and trends in in-conduit hydropower technologies and their applications in water distribution systems," Journal of Environmental Management, vol. 228, pp. 416–428, 2018.

https://doi.org/10.1016/j.jenvman.2018.08.078

|

| [25] |

A. Elbatran, O. Yaakob, A. Y. M. and H. Shabara, "Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review," Renewable and Sustainable Energy Reviews, vol. 43, pp. 40-50, 2015.

http://dx.doi.org/10.1016/j.rser.2014.11.045

|

| [26] |

A. W. Dametew, "Design and Analysis of Small Hydro Power for Rural electrification," Global Journal of Researches in Engineering F Electrical and Electronics Engineering, vol. 16 Issue, pp. 1-23, 2016.

|

| [27] |

R. Uhunmwangho, M. Odje and K. Okedu, "Comparative Analysis of Mini Hydro Turbines for Bumaji Stream, Boki, Cross River State, Nigeria.," Sustain. Energy Technol. Assess, vol. 27, pp. 102-108, 2018.

|

| [28] |

E. Ozer, P. E. AKTAS, K. Mehmet and C. GENCER, "A Literature Review: Wind Energy Within the Scope of MCDM Methods," Journal of Science, vol. 36, no. 4, pp. 1578-1599, 2023.

https://doi.org/10.35378/gujs.1090337

|

| [29] |

D. Sinem, B. Ferhat and S. S. C., "MCDM analysis of wind energy in Turkey: decision making based on environmental impact," Environmental Science and Pollution Research vol. 25, pp. 19753–19766, 2018.

https://doi.org/10.1007/s11356-018-2004-4

|

| [30] |

A. Rubio-Aliaga, M. S. García-Cascales and J. M. Sanchez-Lozano, "MCDM-based multidimensional approach for selection of optimal groundwater pumping systems: Design and case example," Renewable Energy, vol. 163, pp. 213-224, 2021.

https://doi.org/10.1016/j.renene.2020.08.079

|

| [31] |

C. D. Iweh, G. C. S. Ahouansou and R. Houèchénè, "Optimum Site Selection of Hybrid Solar Photovoltaic (PV) - Hydro Power Plants in off Grid Locations in Cameroon using the Multi-Criteria Decision Analysis (MCDA," Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, vol. 45, no. 3, 2023.

https://doi.org/10.1080/15567036.2023.2224739

|

| [32] |

U. Nzotcha, J. Kenfack and M. B. Manjia, "Integrated multi-criteria decision-making methodology for pumped hydro energy storage plant site selection from a sustainable development perspective with an application," Renewable and Sustainable Energy Reviews, vol. 112, p. 930–947, 2019.

https://doi.org/10.1016/j.rser.2019.06.035

|

| [33] |

B. Wang, I. Nistor, T. Murty and Y.-M. Wei, "Efficiency assessment of hydroelectric power plants in Canada: a multi criteria decision making approach," approach. Energy Econ., vol. 46, pp. 112-121, 2014.

https://doi.org/10.1016/j.eneco.2014.09.001

|

| [34] |

R. P. N. H. P. Singh, "Decision aid for hydropower project prioritization in Nepal by applying Visual PROMETHEE," Int. J. Multicriteria Decis. Mak. 6, 316–342, vol. 6, pp. 316–342, 2016.

https://dx.doi.org/10.1504/IJMCDM.2016.081389

|

| [35] |

S. M.´ c. H. S.´. c. I. a. H. S. Stevovic, "Sustainable management of water resources in Prokletije region.," Industrija, vol. 42, pp. 47-61, 2014.

http://dx.doi.org/10.5937/industrija42-4699

|

| [36] |

Y. Wang, S. Tao, X. Chen, F. Huang, X. Xu and al, "Method multi-criteria decision-making method for site selection analysis and evaluation of urban integrated energy stations based on geographic information system," Renewable Energy, vol. 194, pp. 273-292, 2022.

https://doi.org/10.1016/j.renene.2022.05.087

|

| [37] |

B. K. T. M.-K. S. Vucijak and Ceric A, "Applicability of multicriteria decision aid to sustainable hydropower.," Appl. Energy, vol. 101, pp. 261–267., 2013.

https://doi.org/10.1016/j.apenergy.2012.05.024

|

| [38] |

P. Adhikary, S. Kundu, P. K. Roy and A. Mazumdar, "Optimum selection of hydraulic turbine manufacturer for SHP: MCDA or MCDM tools," World Applied Sciences Journal, vol. 28, no. 7, pp. 914-919, 2014.

https://doi.org/10.5829/idosi.wasj.2013.28.07.1373

|

| [39] |

P. Adhikary, P. K. Roy and A. Mazumdar, "Turbine Supplier Selection For Small Hydro Project:" International Journal of Applied Engineering Research, vol. 10, no. 5, pp. 13109-13122, 2015.

|

| [40] |

R. F. d. Silva, M. M. Bellinello and G. F. M. d. Souza, "Deciding a Multicriteria Decision-Making (MCDM) Method to Prioritize Maintenance Work Orders of Hydroelectric Power Plants," energies, vol. 14, pp. 2-22 2021.

https://doi.org/10.3390/en14248281

|

| [41] |

Y. H. Chang, C. Cheng and T. Wang, "Performance evaluation of international airports in the region of East Asia.," Proceedings of Eastern Asia Society for Transportation Studies, vol. 4, pp. 213–230, 2003.

|

| [42] |

T. Y. Chou and G. S. Liang, "Application of a fuzzy multi-criteria decision-making model for shipping company performance evaluation.," Maritime Policy & Management, 28, 375–392., vol. 4, p. 375–392., 2001.

|

| [43] |

G. Büyükzokan, O. Feyzioglu and E. Nebol, "Selection of the strategic alliance partner in logistics value chain," ternational Journal of Production Economics, vol. 113, p. 148–158, 2008.

|

| [44] |

H. Y. and C. H. Y. e. W. S., "A survey and optimization-based evaluation of development strategies for the air cargo industry.," International journal of Production Economics, 106, 550–562, vol. 106, p. 550–562, 2007.

https://doi.org/10.1016/j.ijpe.2006.06.016

|

| [45] |