Large-scale agricultural production generally occurs during specific periods of the year. This results in the unavailability of products outside of their production periods. Due to their high water content, most agri-food products deteriorate very quickly under the effect of heat, hence the need to develop preservation techniques. Preservation techniques for fresh produce require energy. Burkina Faso is a country with strong solar potential, which is why solar dryers are the most developed technologies for preserving agri-food products. However, the quality of the dried product depends on the quality of the dryer. Our work focuses on the construction of a mixed solar dryer for drying agricultural products. The flat-plate collector is equipped with baffles that allow for greater heat exchange between the air and the hot parts (absorber and baffles) of the collector. The drying chamber is fitted with double-sloped glazing on the roof. An experimental study of hygrothermal parameters, such as air temperature at the racks, product temperature, product water content, and relative humidity inside the drying chamber, was conducted to determine the dryer's performance. We also determined the effective diffusion coefficient and efficiency. The evolution of solar irradiation was monitored during drying operations. Experiments show that the temperature inside the dryer can reach 80°C to 100°C. The effective diffusion coefficient is approximately 1.89.10-7 m2/s, and the dryer's efficiency is 28.56%.

| Published in | Science Research (Volume 13, Issue 5) |

| DOI | 10.11648/j.sr.20251305.11 |

| Page(s) | 128-135 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Mixed Solar Dryer, Okra, Drying Kinetics, Temperature, Efficiency

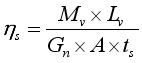

(2)

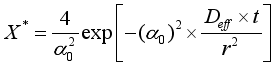

(2)  (3)

(3)

| Water Content at Time t(s) |

| Mass at Time t(s) |

| Dry Mass (kg) |

| Overall Efficiency of the Dryer |

Mv | Mass of Water Evaporated During the Total Drying Time (kg) |

Lv | Latent Heat of Vaporization in (j/kg) |

Gn | Average Daily Solar Radiation on the Dryer Surface (w/m2) |

A | Area of the Absorber Exposed to solar Radiation (m2) |

ts | Drying Time (s) |

Deff | Diffusion Coefficient (m2.s-1) |

X* | Reduced Water Content |

r | Product Radius (m) |

α0 | Bessel Function of Order 0 |

t | Time (s) |

| [1] | Diemuodeke E. OGHENERUONA, Momoh O. L. YUSUF. Design and Fabrication of a direct natural convection solar dryer for tapioca”, Leonardo Electronic Journal of Practices and Technologies, 2011, (18). |

| [2] | Eke, Ben Akachukwu. Development of small scale direct mode natural convection solar dryer for tomato, okra and carrot, International Journal of Engineering and Technology, 2013, 3 (2). |

| [3] | Atul Sharma, C. R. Chen, Nguyen Vu Lan. Solar-energy drying systems: A review”, Renewable and Sustainable Energy Reviews, 2009, (13), |

| [4] | Bayopo, S. O. and Alonge, O. I. Development and Quality Analysis of a direct solar dryer for fish. Food and Nutrition Sciences, 2018, (9), |

| [5] | Tefera A, Endalew W and Fikiru B. Evaluation and demonstration of direct solar potato dryer. Livestock Research for Rural Development, 2013, 25(12). |

| [6] | DIANDA Boureima, OUEDRAOGO Emmanuel, BADO Nébon, TRAORE Abdoul Fataho, NANA Gilbert, KY S. M Thierry, BATHIEBO Dieudonné Joseph. Numerical study of papaya drying in a solar dryer, JCBPS; Section C;), 2024, 14(3), |

| [7] | Thierry Sikoudouin Maurice KY, Damus Abdoul Aziz Traoré, Bienvenu Magloire Pakouzou, Boureima Dianda, Emmanuel Ouedraogo et Dieudonné Joseph Bathiébo. Expermiental study of an indirect solar dryer using a new collector system: Application to Mango and Ginger Drying, Contemporary Engenering science, 2021, 14(1). |

| [8] | S. Esakkimuthu, Abdel Hakim Hassabou, C. Palaniappan, Markus Spinnler, Jurgen Blumenberg, R. Velraj. Experimental investigation on phase change material based thermal storage system for solar air heating applications. Solar Energy, 2013, (88). |

| [9] | V. Shanmugam, E. Natarajan. Experimental study of regenerative desiccant integrated solar dryer with and without reflective mirror. Applied Thermal Engineering, 2007, 27(8-9). |

| [10] | S. Shanmugam, P. Kumar AR., Veerappan. Modeling and Experimental Studies on Oscillating Inclined-Bed Solar Dryer. Journal of Solar Energy Engineering, 2013, (135). |

| [11] | P. N. Sarsavadia. Development of a solarassisted dryer and evaluation of energy requirement for the drying of onion. Renewable Energy, 2007, (32). |

| [12] | F. K. Forson, M. A. A. Nazha, H. Rajakaruna. Modelling and experimental studies on a mixed-mode natural convection solar crop-dryer, Solar Energy, 2007, (81). |

| [13] | Bukola O. Bolaji and Ayoola P. Olalusi, Performance Evaluation of a Mixed-Mode Solar Dryer, AU J. T. 2008, 11(4). |

| [14] | López-Vidaña Erick César, César-Munguía Ana Lilia, García-Valladares Octavio, Pilatowsky Figueroa Isaac, Brito Orosco Rogelio. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum), Renewable Energy, 2019, |

| [15] | Ahmed Djeblia, Salah Haninia, Ouassila Badaouia, Mouloud Boumahdia, A new approach to the thermodynamics study of drying tomatoes in mixed solar dryer, Solar Energy, 2019,(193). |

| [16] | Ikechukwu Celestine Ugwuoke, Ibukun Blessing Ikechukwu, Ogbe Eric Ifianyi. Design and Development of a Mixed-Mode Domestic Solar Dryer, I. J. Engineering and Manufacturing, 2019, (3). |

| [17] | Chandrakumar B Pardhi and Jiwanlal L Bhagoria. Development and performance evaluation of mixed-mode solar dryer with forced convection, International Journal of Energy and Environmental Engineering, 2013, (4). |

| [18] | Dianda Boureima, Traore Abdoul Fataho, Ouedraogo Adama, KY Sikoudouin Maurice Thierry, Ouedraogo Issaka a, Kam Sié and Bathiébo Dieudonné. Experimental Study of Papaya Drying in an Indirect Solar Dryer in Natural Convection, Current Journal of Applied Science and Technology, 2022, 41(32). |

| [19] | Ramadan El Gamal, Frederik Ronsse, Jan G. Pieters. Modeling Deep-Bed Grain Drying Using COMSOL Multiphysics, excerptfrom the proceedings of the comsol conference in Rotterdam, 2013 |

| [20] | DIANDA Boureima, KY Thierry S. M., COMPAORE Abdoulaye, GUENGANE Hassim, OUEDRAOGO Salifou and BATHIEBO D. Joseph. Modeling of tomato convective drying with comsol software, Asian Journal of Science and Technology, 2019, 10(8). |

| [21] | Boureima Dianda, Labayè Yves Japhet Koussoubé, Lareba Adélaïde Ouédraogo, Moctar Ousmane and Dieudonné Joseph Bathiébo. Realization and Experimental Study of a Forced Convection Solar Dryer, Asian Journal of Physical and Chemical Sciences, 2024, 12(2). |

| [22] | Dianda B, Ousmane M., Kam S., Ky T. and Bathiébo D. J. Experimental study of the kinetics and shrinkage ofntomato slices in convective drying, African journal of food science, 2015, 9(5). |

| [23] | T. J. Afolabi, Thin Layer Drying Kinetics and Modelling of Okra (Abelmoschus Esculentus (L.) Moench) Slices under Natural and Forced Convective Air Drying, Food Science and Quality Management, 2014, (28). |

| [24] | Arslan Afzal, Tahir Iqbal, Kamran Ikram, Muhammad Naveed Anjum, Muhammad Umair, Muhammad Azam, Sajeela Akram, Fiaz Hussain, Muhammad Ameen ul Zaman, Abid Ali, Faizan Majeed. Development of a hybrid mixed-mode solar dryer for product drying, Heliyon, 2003, (9) e14144. |

| [25] | Kritsna Mongkolkerd and Siva Achariyaviriya. Effective diffusion coefficient of okra during hot air drying, Interdisciplinary Research and Development in ASEAN Universities, 2013, 2(1). |

| [26] | Ouoba Kondia Honoré, Zougmoré François, Sam Raguilignaba, Toguyeni Aboubacar, Desmorieux Hélène. Characterization of okra convective drying, influence of maturity. Food and Nutrition Sciences, Food and Nutrition Sciences, 2014, (5). |

| [27] | Germain Wende Pouiré Ouedraogo, Boureima Kaboré, Sié Kam, Dieudonné Joseph Bathiébo. Determination of Physical and Chemical Properties of Okra During Convective Solar Drying. International Journal of Engineering and Advanced Technology, 2007, 7(1). |

| [28] | Go¨kc¸e Dadalı, Dilek Kılıc¸ Apar, and Belma O ¨ zbek. Estimation of Effective Moisture Diffusivity of Okra for Microwave Drying, Drying Technology, 2007, (25). |

| [29] | Lakshmi DVN, Muthukumar P, Layek A, Nayak PK. Drying kinetics and quality analysis of black turmeric (Curcuma caesia) drying in a mixed mode forced convection solar dryer integrated with thermal energy storage, Renewable Energy, 2018. |

APA Style

Boureima, D., Pouiré, O. G. W., Safiatou, A., Sié, K., Joseph, B. D. (2025). Experimental Study of a Mixed Solar Dryer: Application to Drying Okra. Science Research, 13(5), 128-135. https://doi.org/10.11648/j.sr.20251305.11

ACS Style

Boureima, D.; Pouiré, O. G. W.; Safiatou, A.; Sié, K.; Joseph, B. D. Experimental Study of a Mixed Solar Dryer: Application to Drying Okra. Sci. Res. 2025, 13(5), 128-135. doi: 10.11648/j.sr.20251305.11

@article{10.11648/j.sr.20251305.11,

author = {Dianda Boureima and Ouédraogo Germain Wende Pouiré and Aoué Safiatou and Kam Sié and Bathiébo Dieudonné Joseph},

title = {Experimental Study of a Mixed Solar Dryer: Application to Drying Okra

},

journal = {Science Research},

volume = {13},

number = {5},

pages = {128-135},

doi = {10.11648/j.sr.20251305.11},

url = {https://doi.org/10.11648/j.sr.20251305.11},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.sr.20251305.11},

abstract = {Large-scale agricultural production generally occurs during specific periods of the year. This results in the unavailability of products outside of their production periods. Due to their high water content, most agri-food products deteriorate very quickly under the effect of heat, hence the need to develop preservation techniques. Preservation techniques for fresh produce require energy. Burkina Faso is a country with strong solar potential, which is why solar dryers are the most developed technologies for preserving agri-food products. However, the quality of the dried product depends on the quality of the dryer. Our work focuses on the construction of a mixed solar dryer for drying agricultural products. The flat-plate collector is equipped with baffles that allow for greater heat exchange between the air and the hot parts (absorber and baffles) of the collector. The drying chamber is fitted with double-sloped glazing on the roof. An experimental study of hygrothermal parameters, such as air temperature at the racks, product temperature, product water content, and relative humidity inside the drying chamber, was conducted to determine the dryer's performance. We also determined the effective diffusion coefficient and efficiency. The evolution of solar irradiation was monitored during drying operations. Experiments show that the temperature inside the dryer can reach 80°C to 100°C. The effective diffusion coefficient is approximately 1.89.10-7 m2/s, and the dryer's efficiency is 28.56%.

},

year = {2025}

}

TY - JOUR T1 - Experimental Study of a Mixed Solar Dryer: Application to Drying Okra AU - Dianda Boureima AU - Ouédraogo Germain Wende Pouiré AU - Aoué Safiatou AU - Kam Sié AU - Bathiébo Dieudonné Joseph Y1 - 2025/09/11 PY - 2025 N1 - https://doi.org/10.11648/j.sr.20251305.11 DO - 10.11648/j.sr.20251305.11 T2 - Science Research JF - Science Research JO - Science Research SP - 128 EP - 135 PB - Science Publishing Group SN - 2329-0927 UR - https://doi.org/10.11648/j.sr.20251305.11 AB - Large-scale agricultural production generally occurs during specific periods of the year. This results in the unavailability of products outside of their production periods. Due to their high water content, most agri-food products deteriorate very quickly under the effect of heat, hence the need to develop preservation techniques. Preservation techniques for fresh produce require energy. Burkina Faso is a country with strong solar potential, which is why solar dryers are the most developed technologies for preserving agri-food products. However, the quality of the dried product depends on the quality of the dryer. Our work focuses on the construction of a mixed solar dryer for drying agricultural products. The flat-plate collector is equipped with baffles that allow for greater heat exchange between the air and the hot parts (absorber and baffles) of the collector. The drying chamber is fitted with double-sloped glazing on the roof. An experimental study of hygrothermal parameters, such as air temperature at the racks, product temperature, product water content, and relative humidity inside the drying chamber, was conducted to determine the dryer's performance. We also determined the effective diffusion coefficient and efficiency. The evolution of solar irradiation was monitored during drying operations. Experiments show that the temperature inside the dryer can reach 80°C to 100°C. The effective diffusion coefficient is approximately 1.89.10-7 m2/s, and the dryer's efficiency is 28.56%. VL - 13 IS - 5 ER -